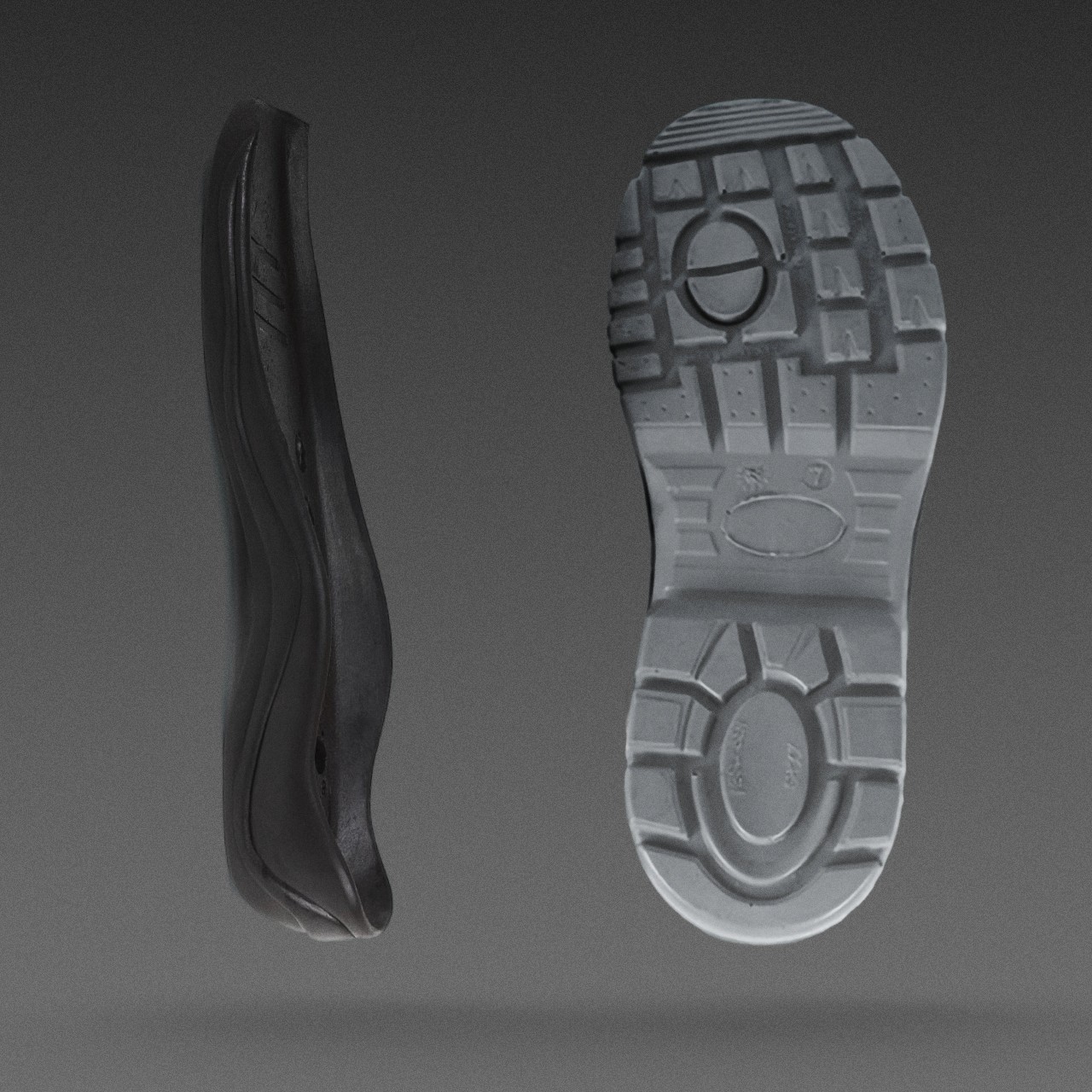

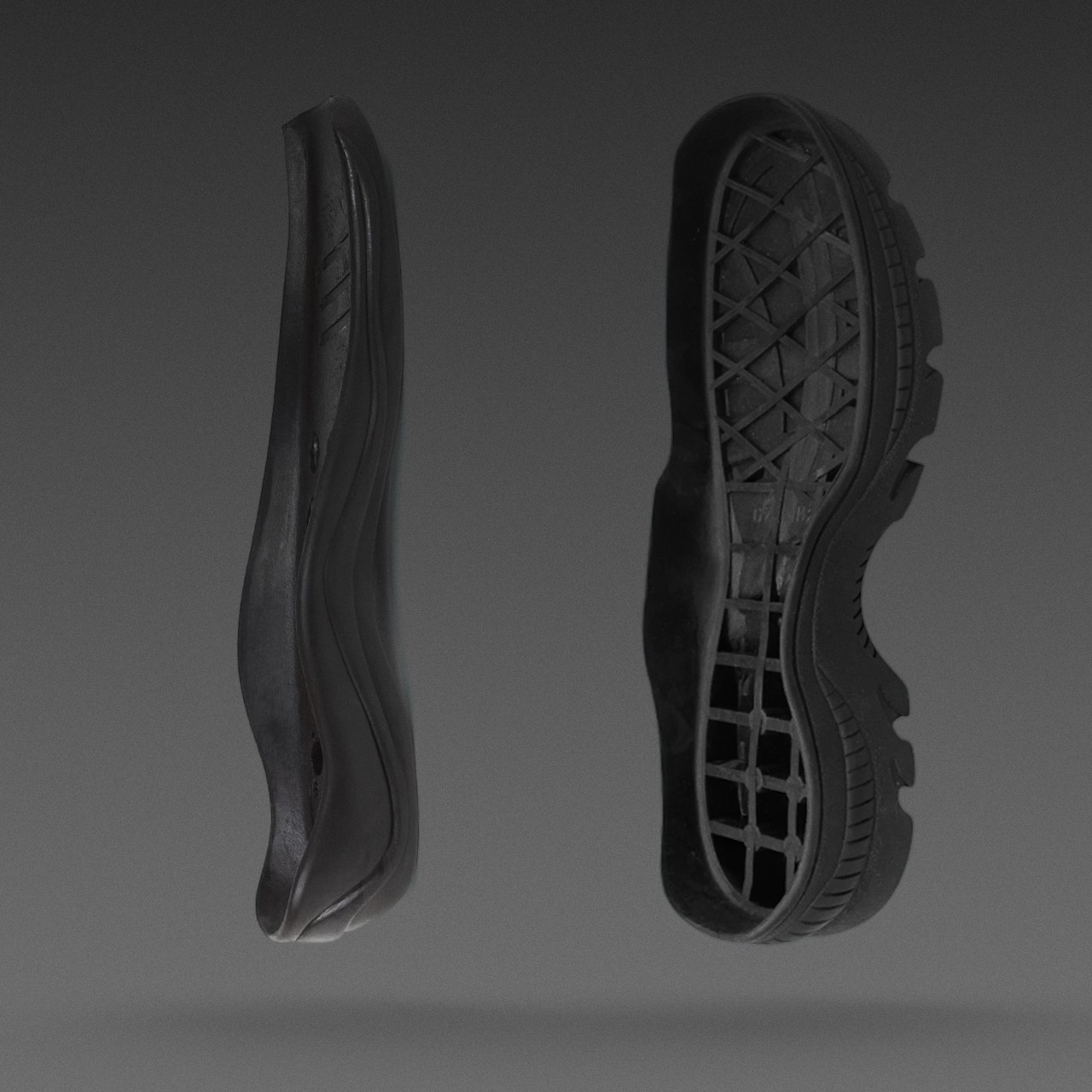

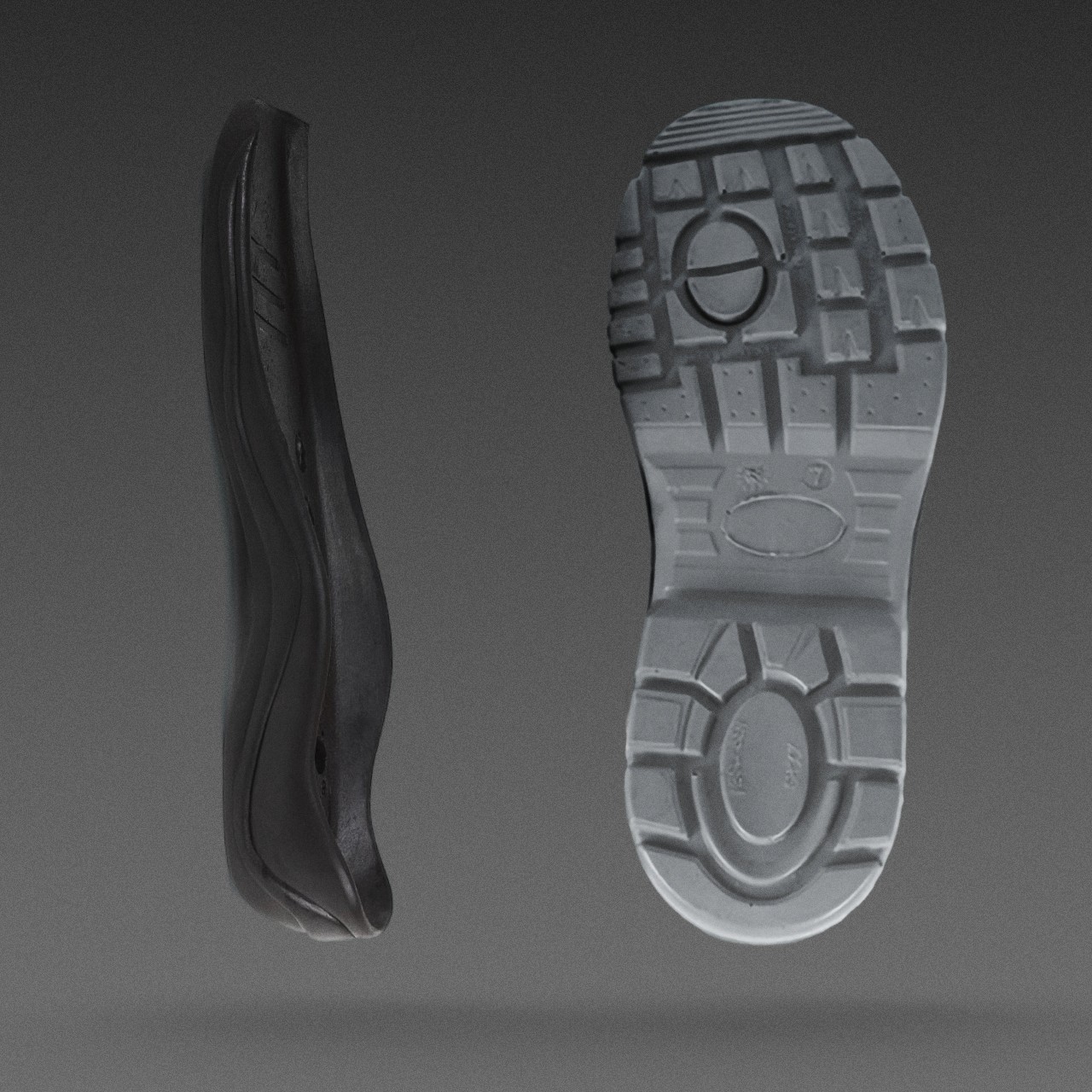

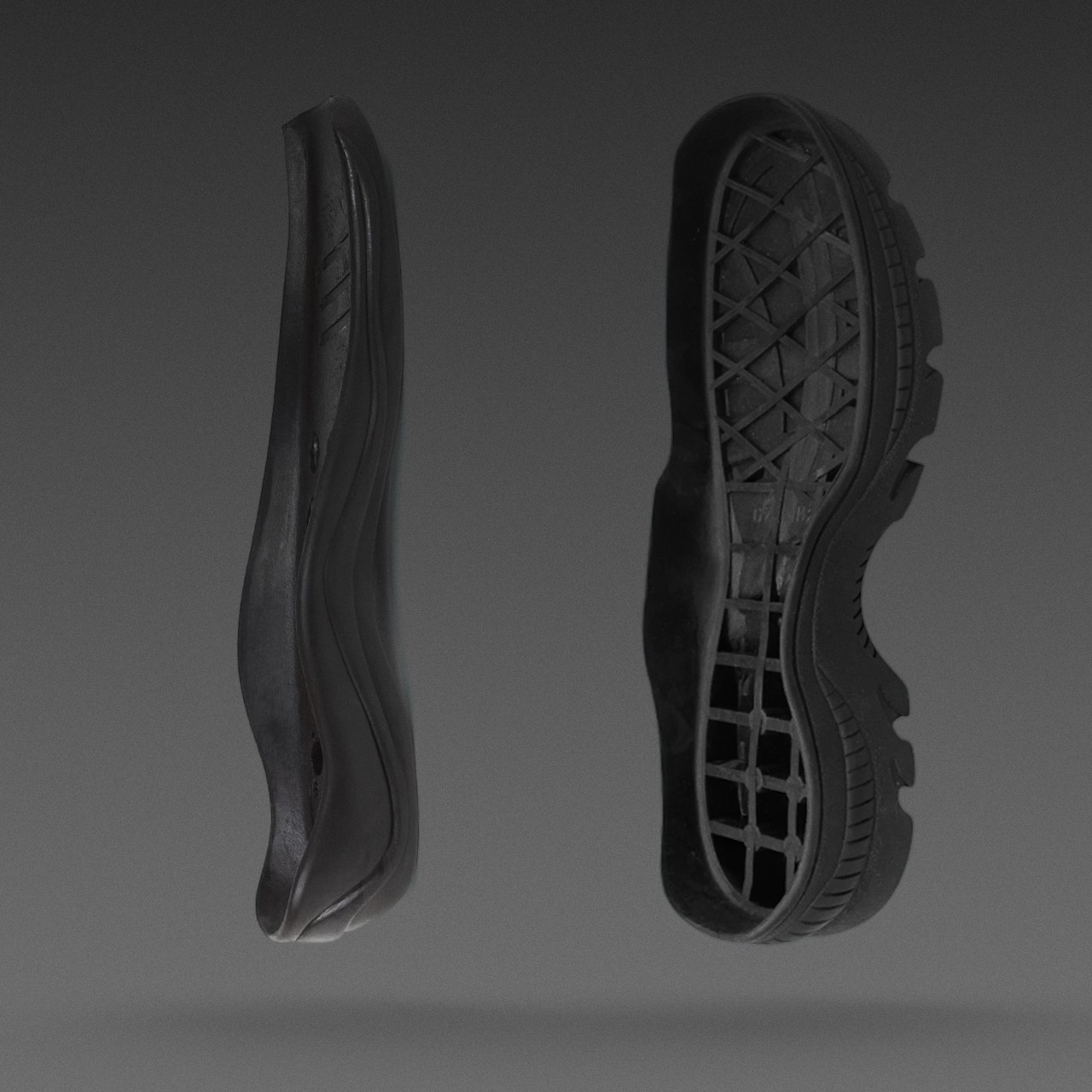

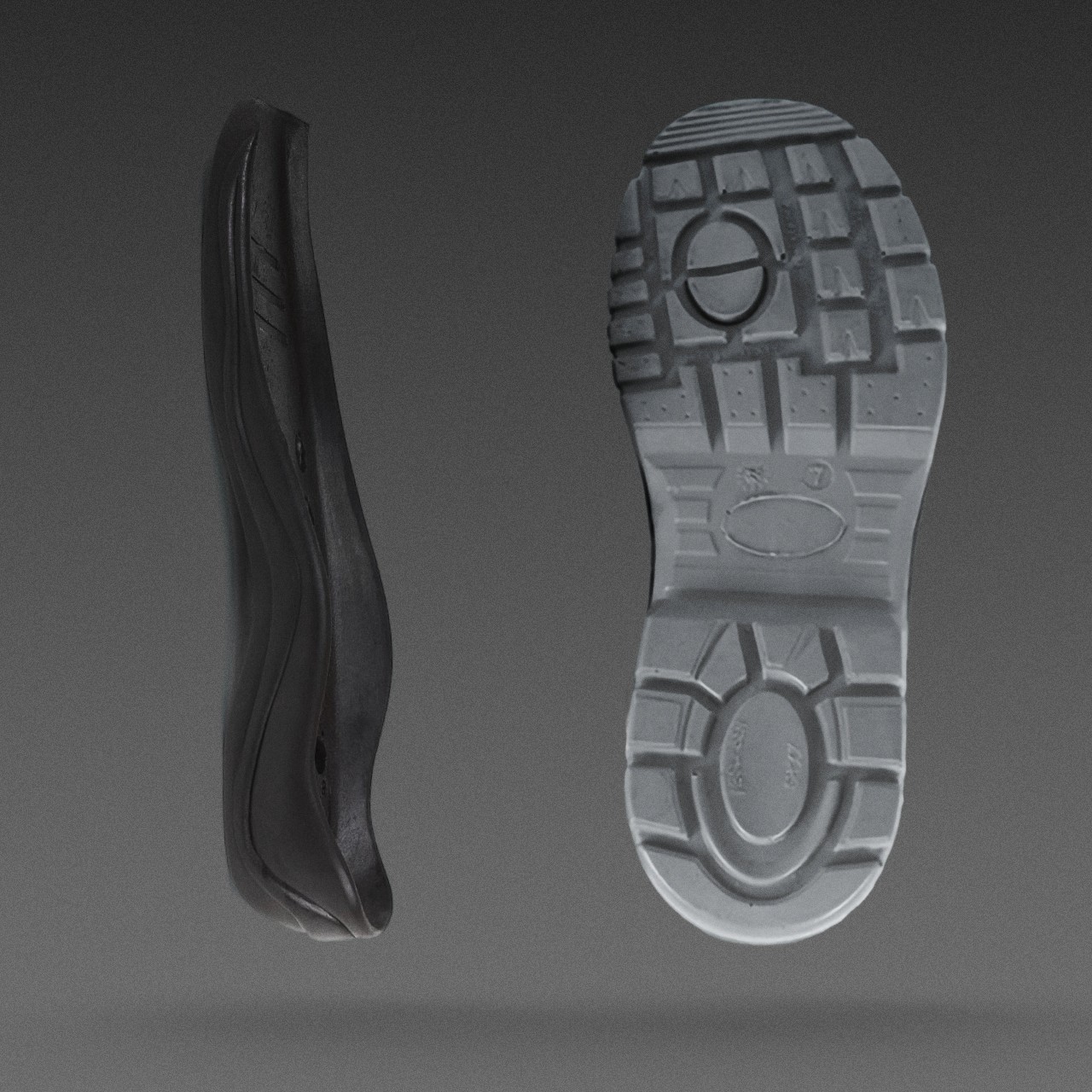

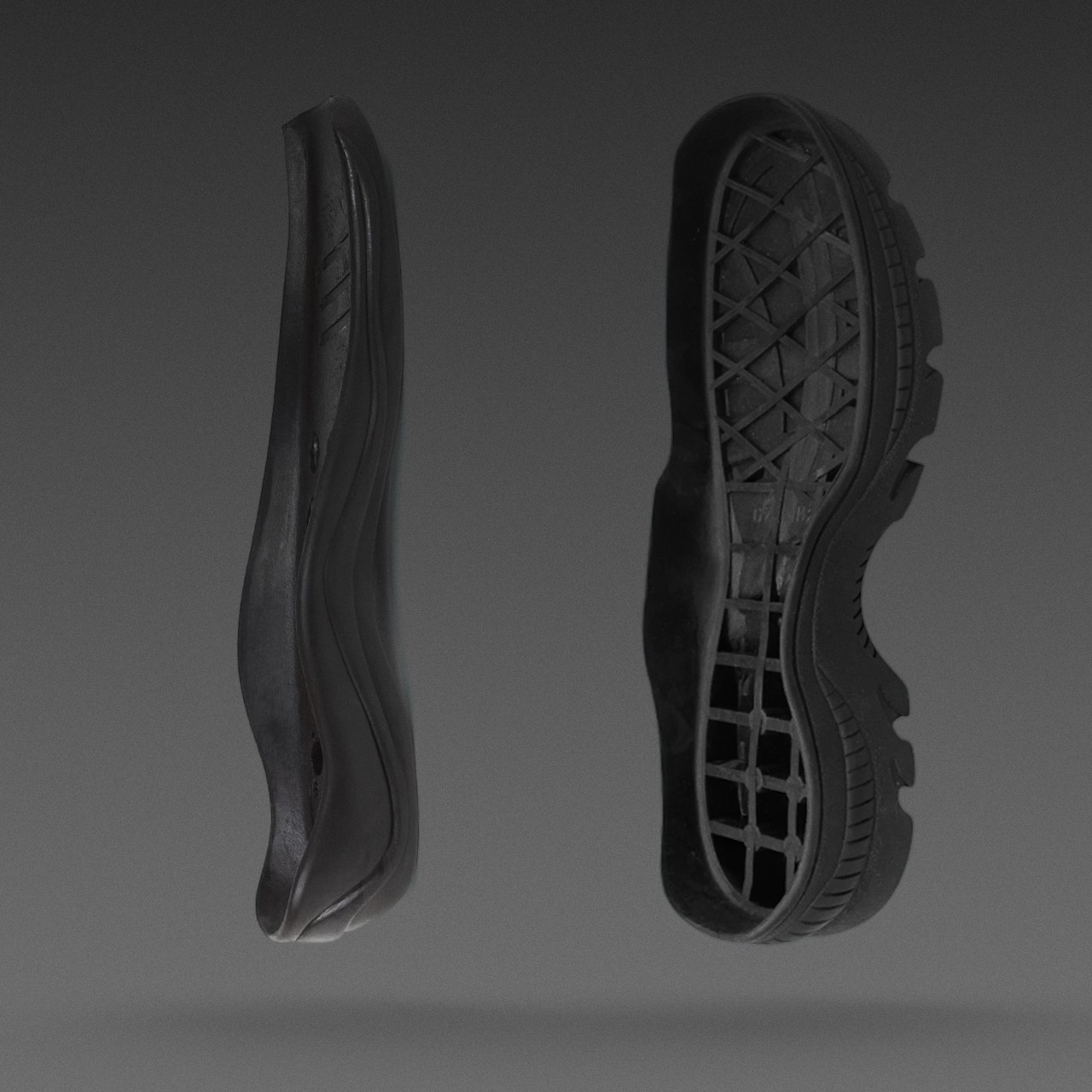

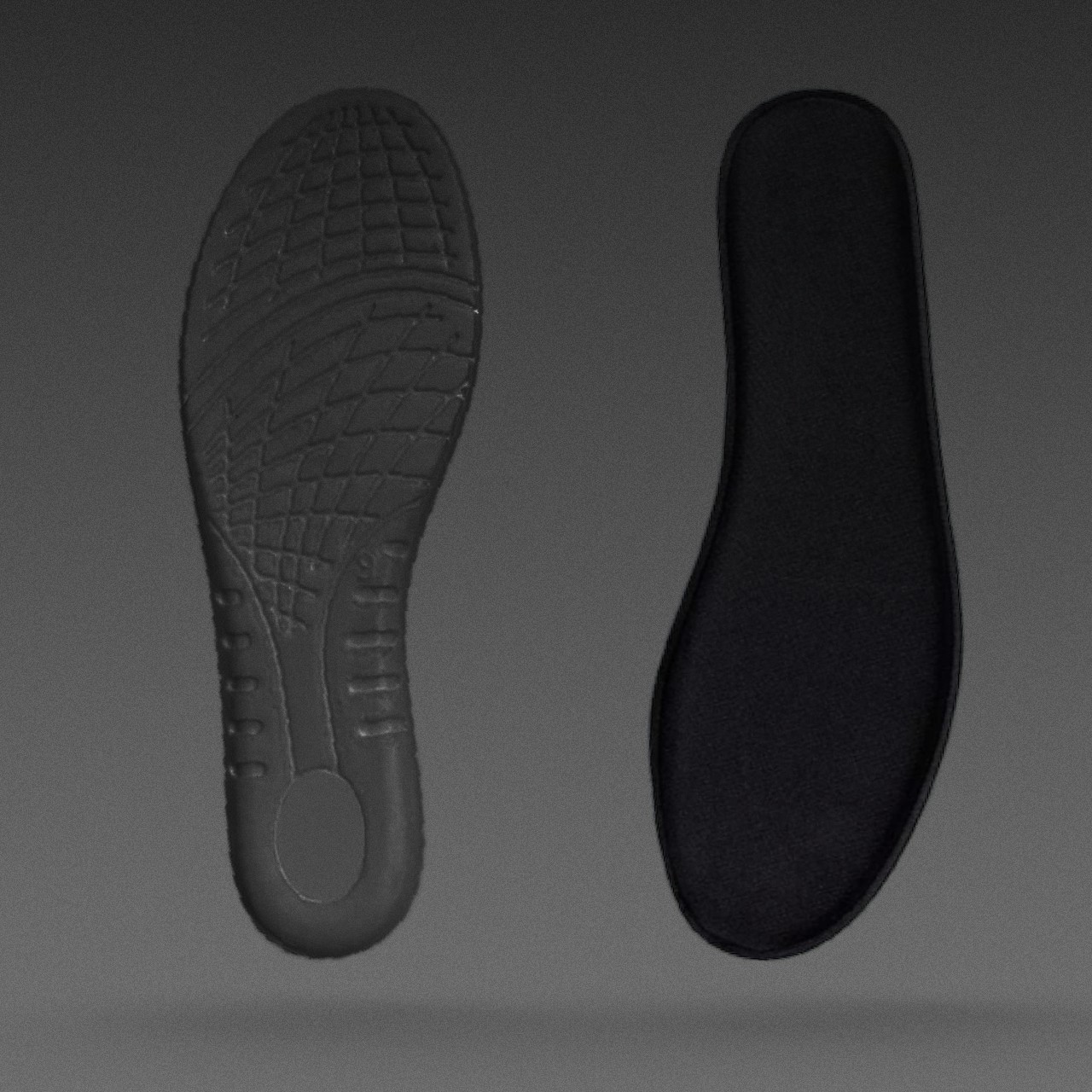

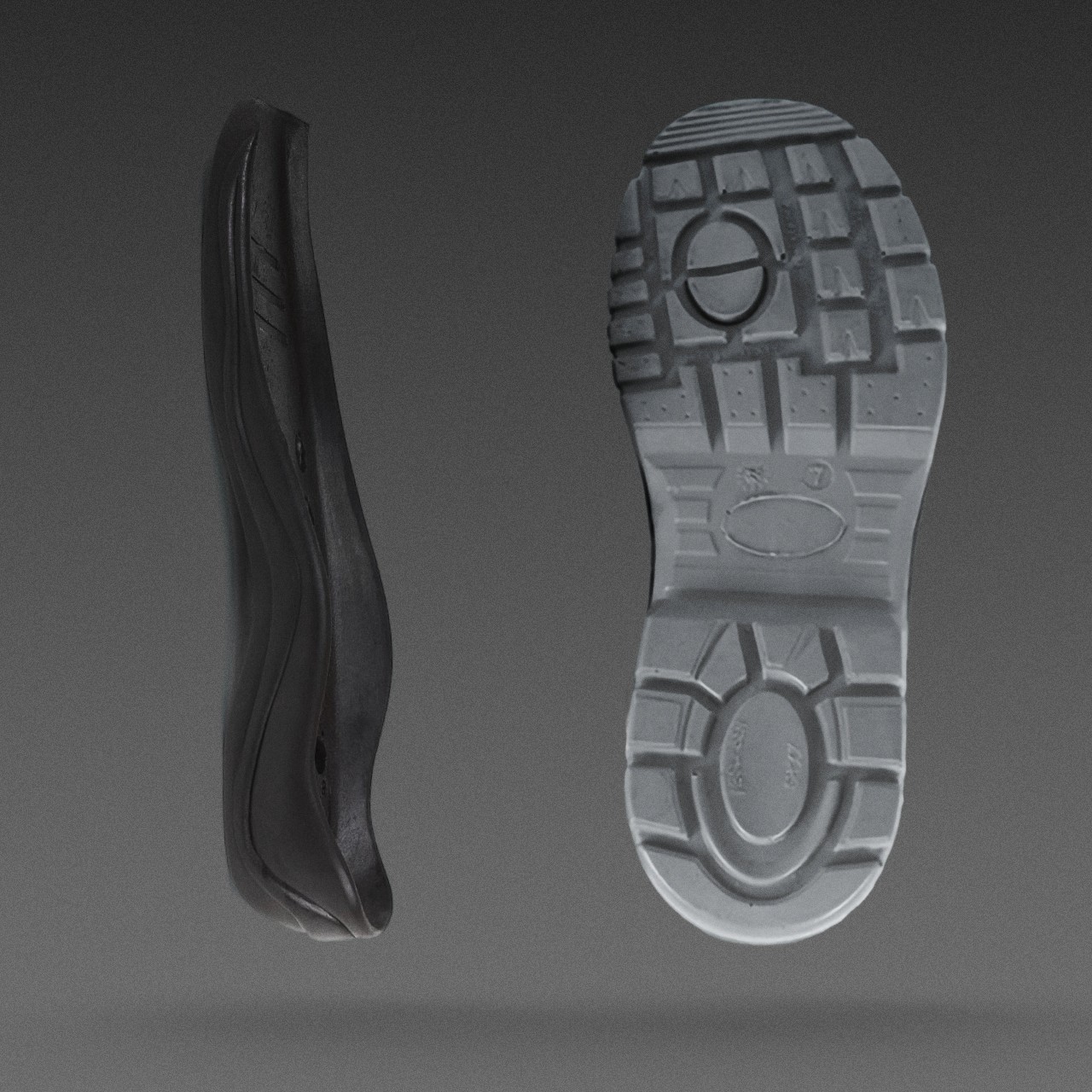

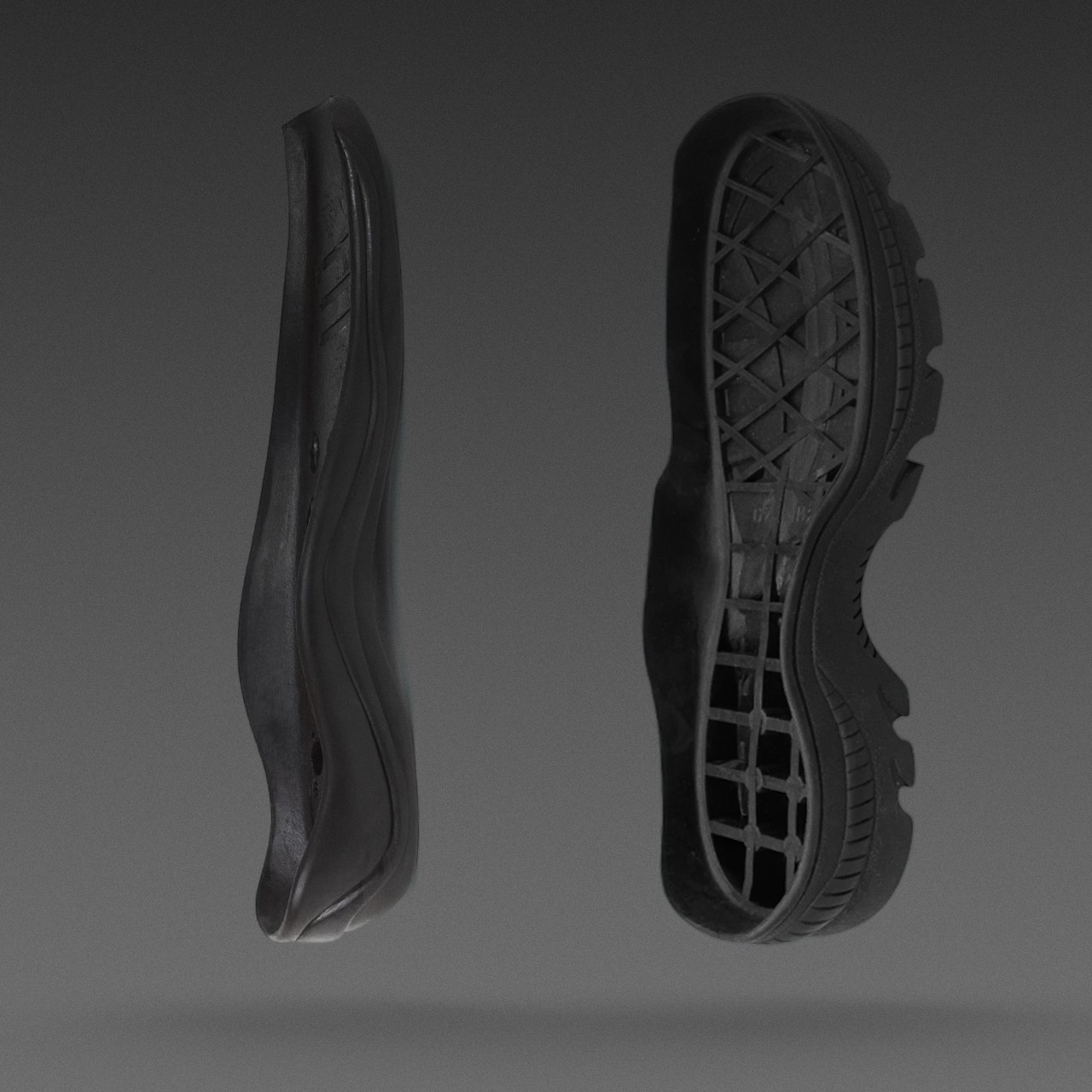

Soles

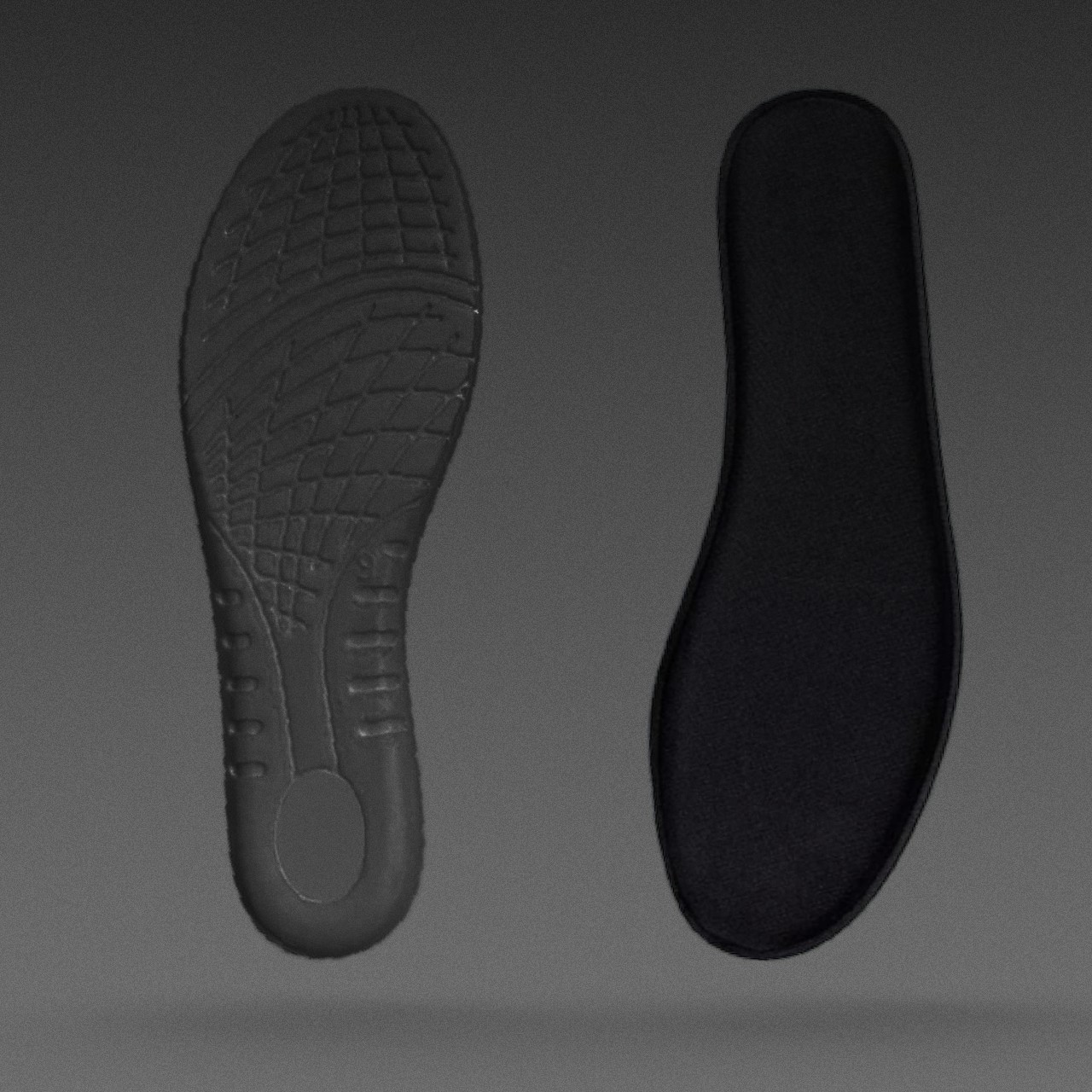

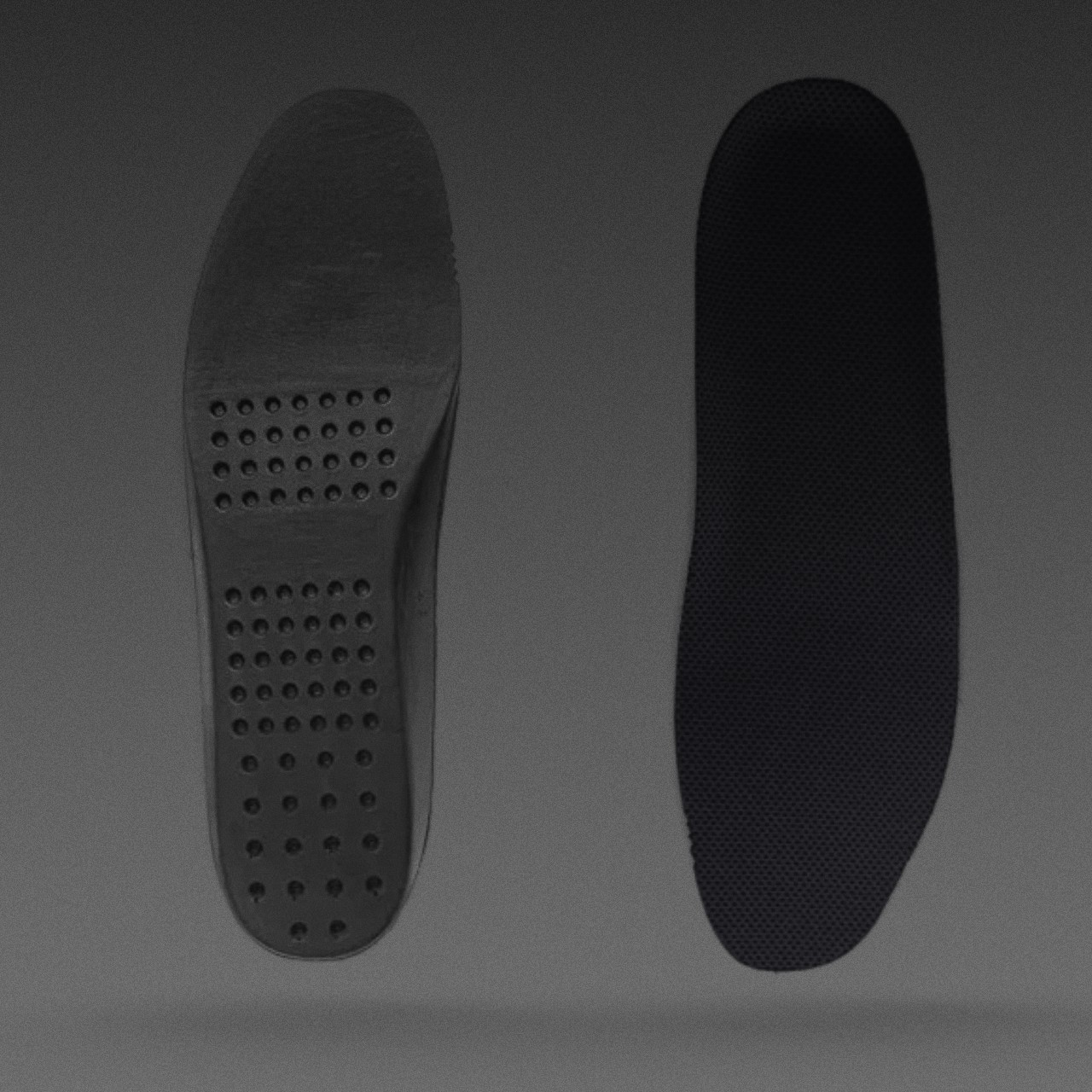

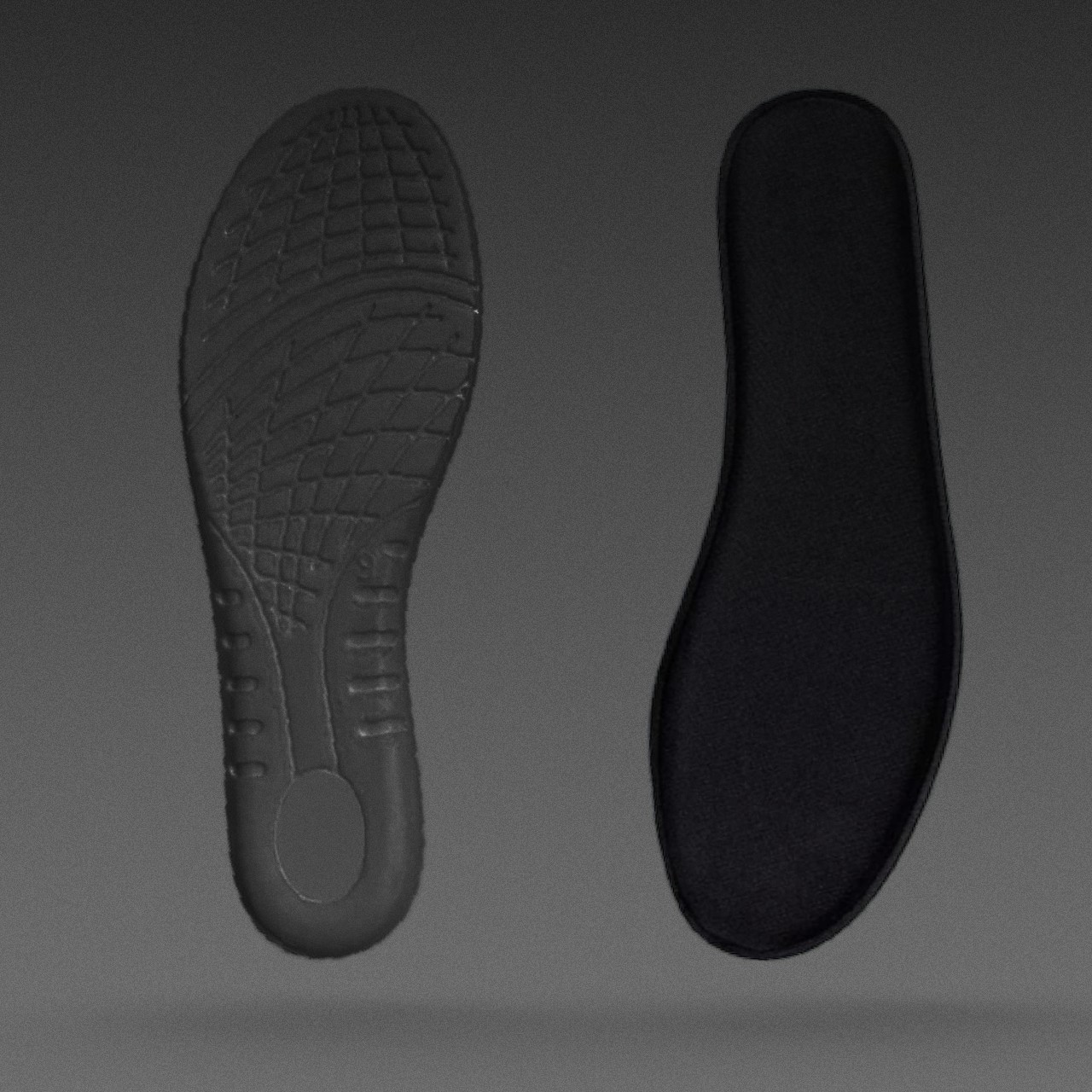

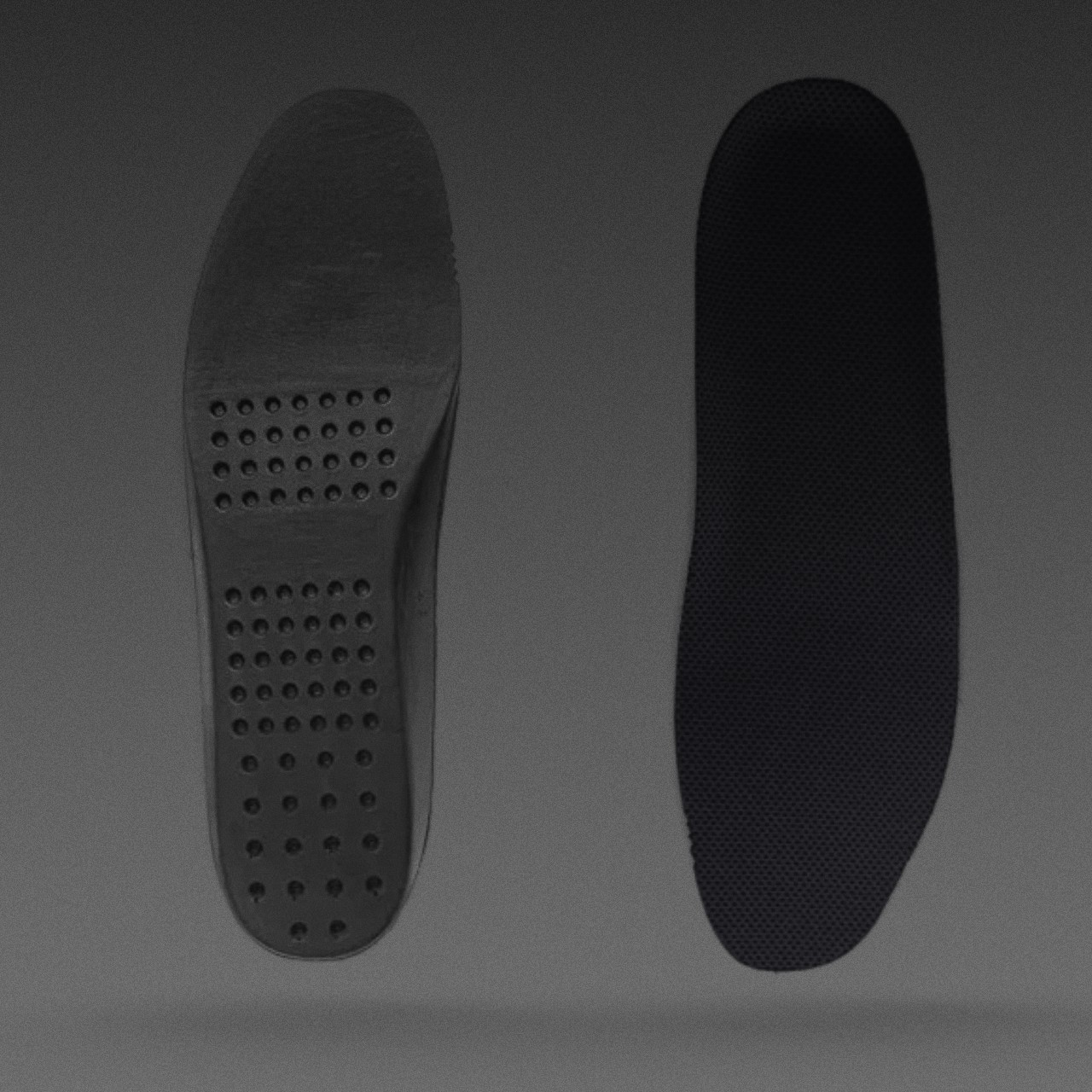

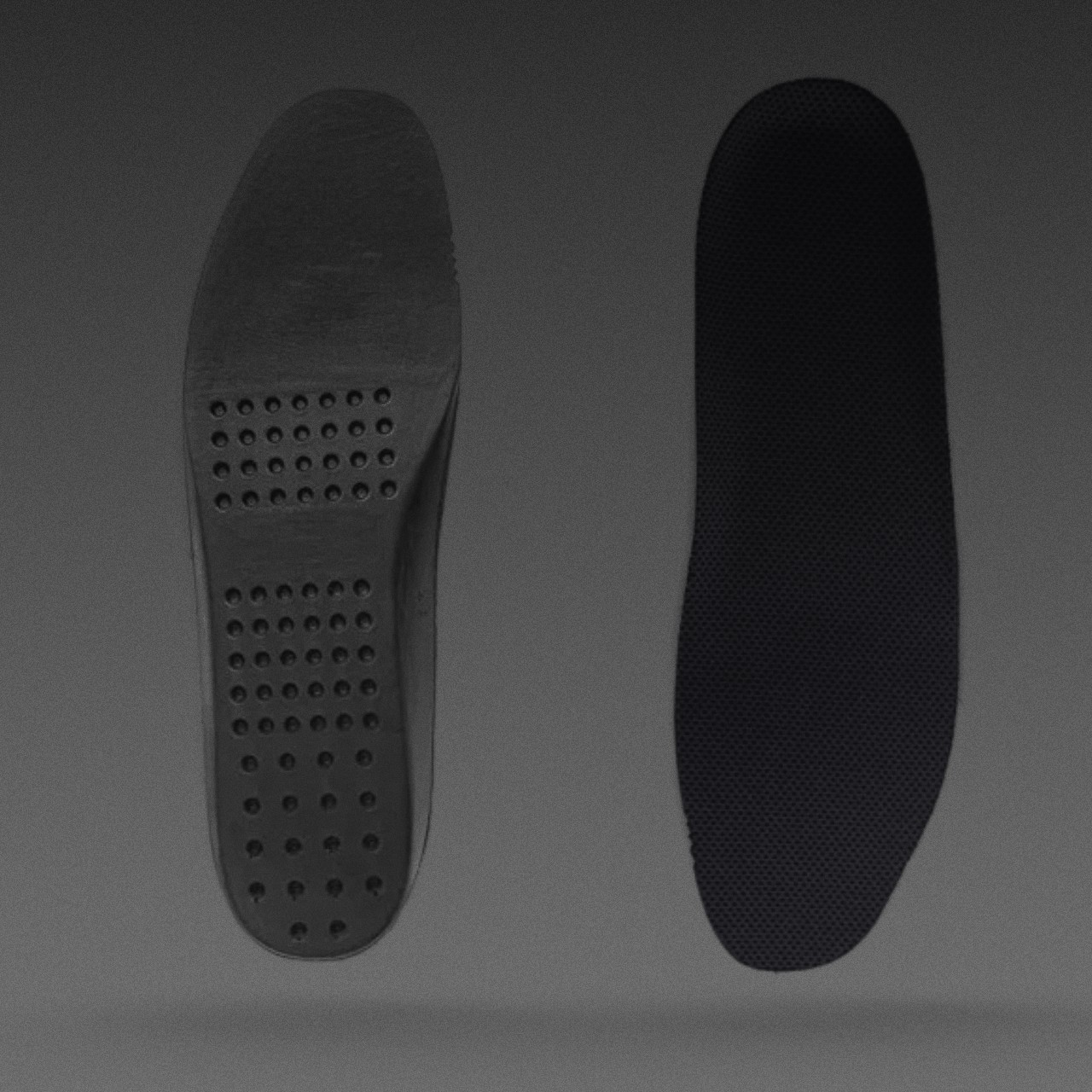

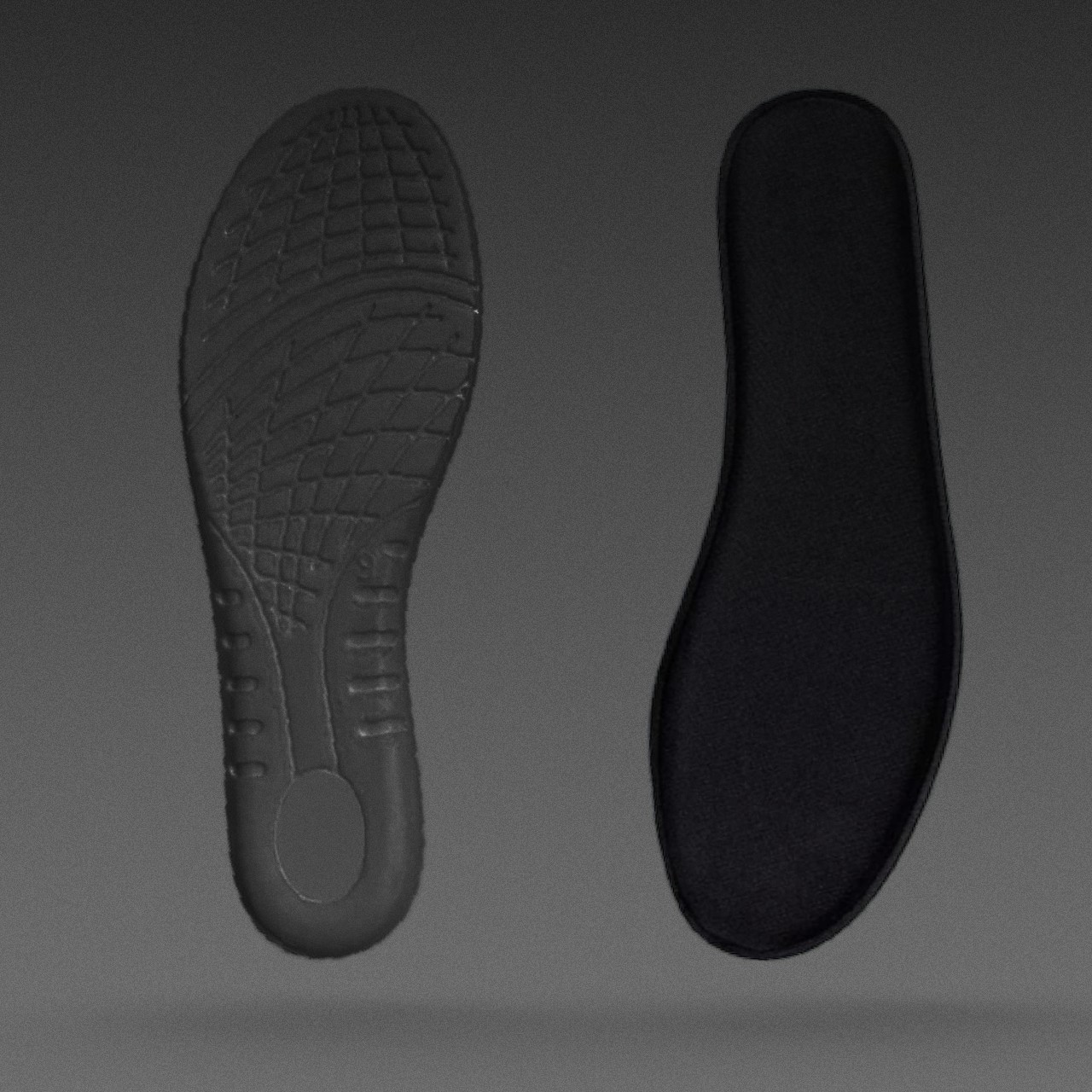

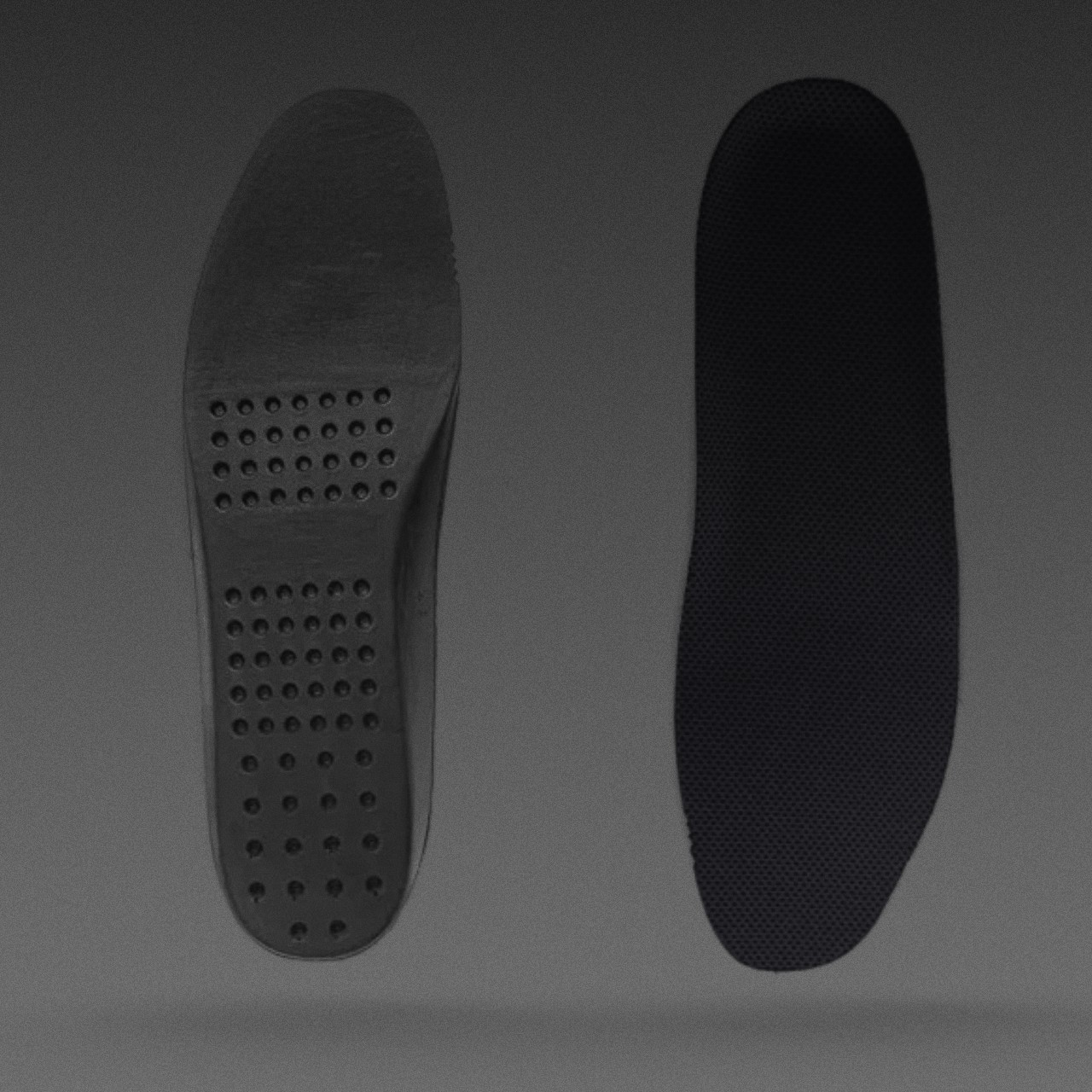

Insock

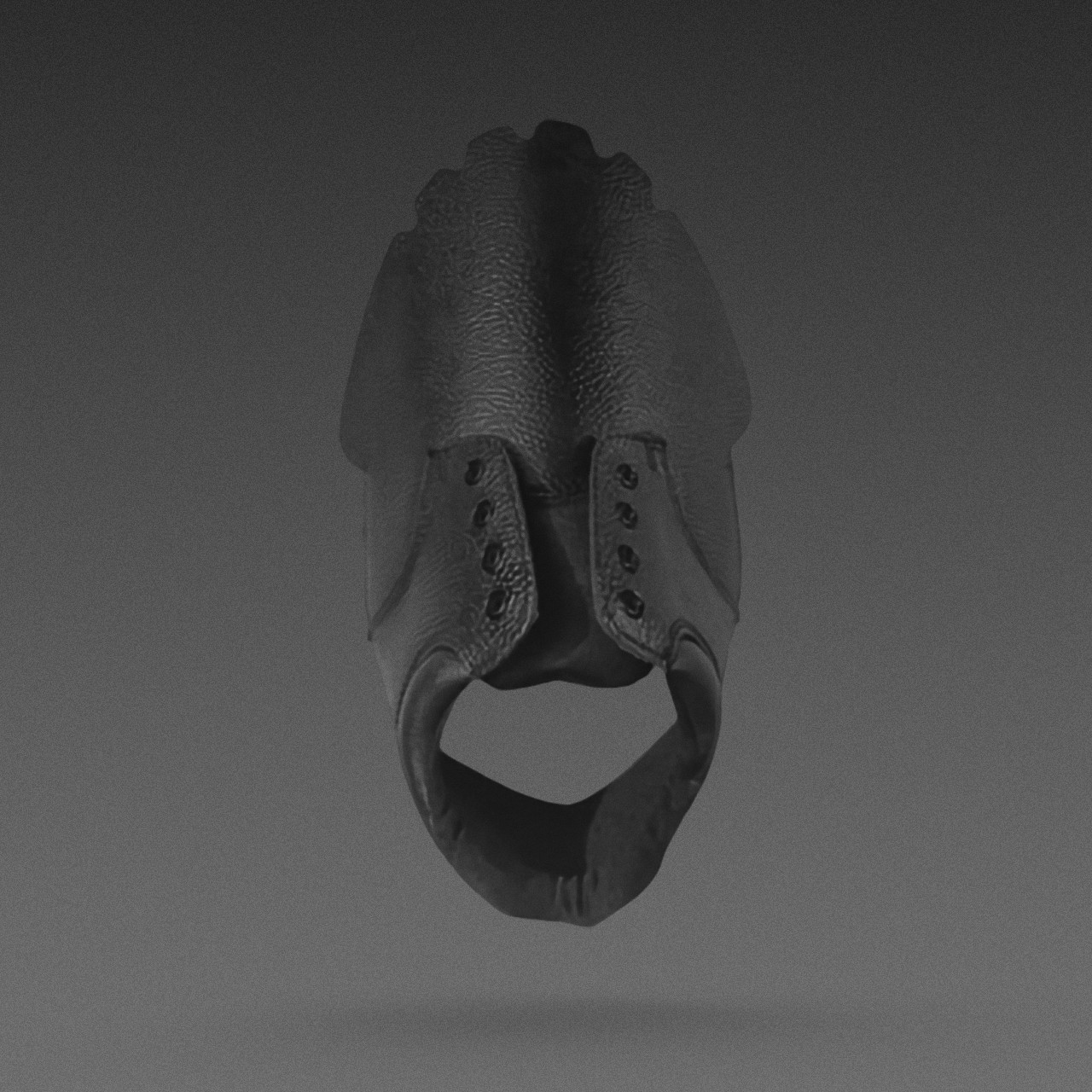

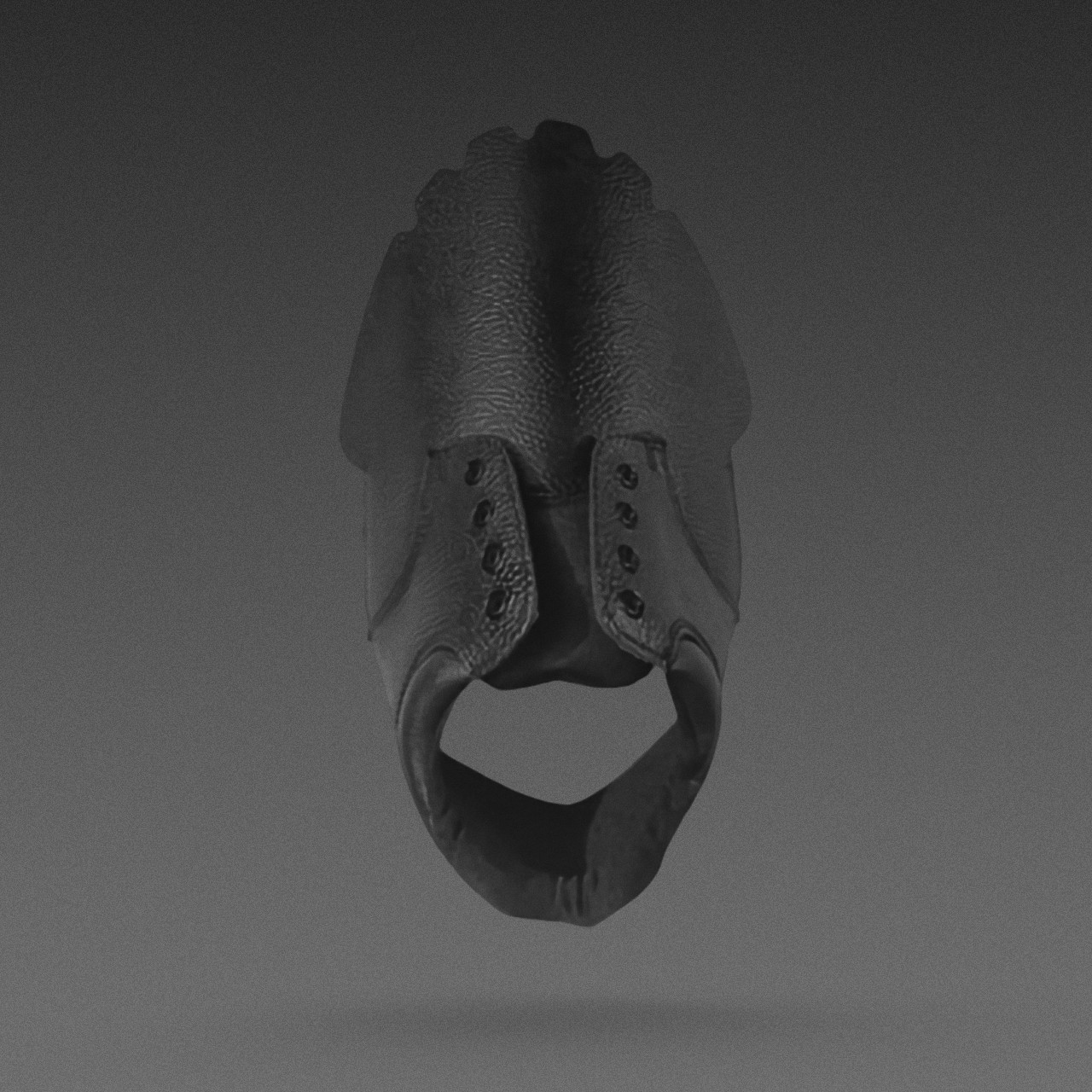

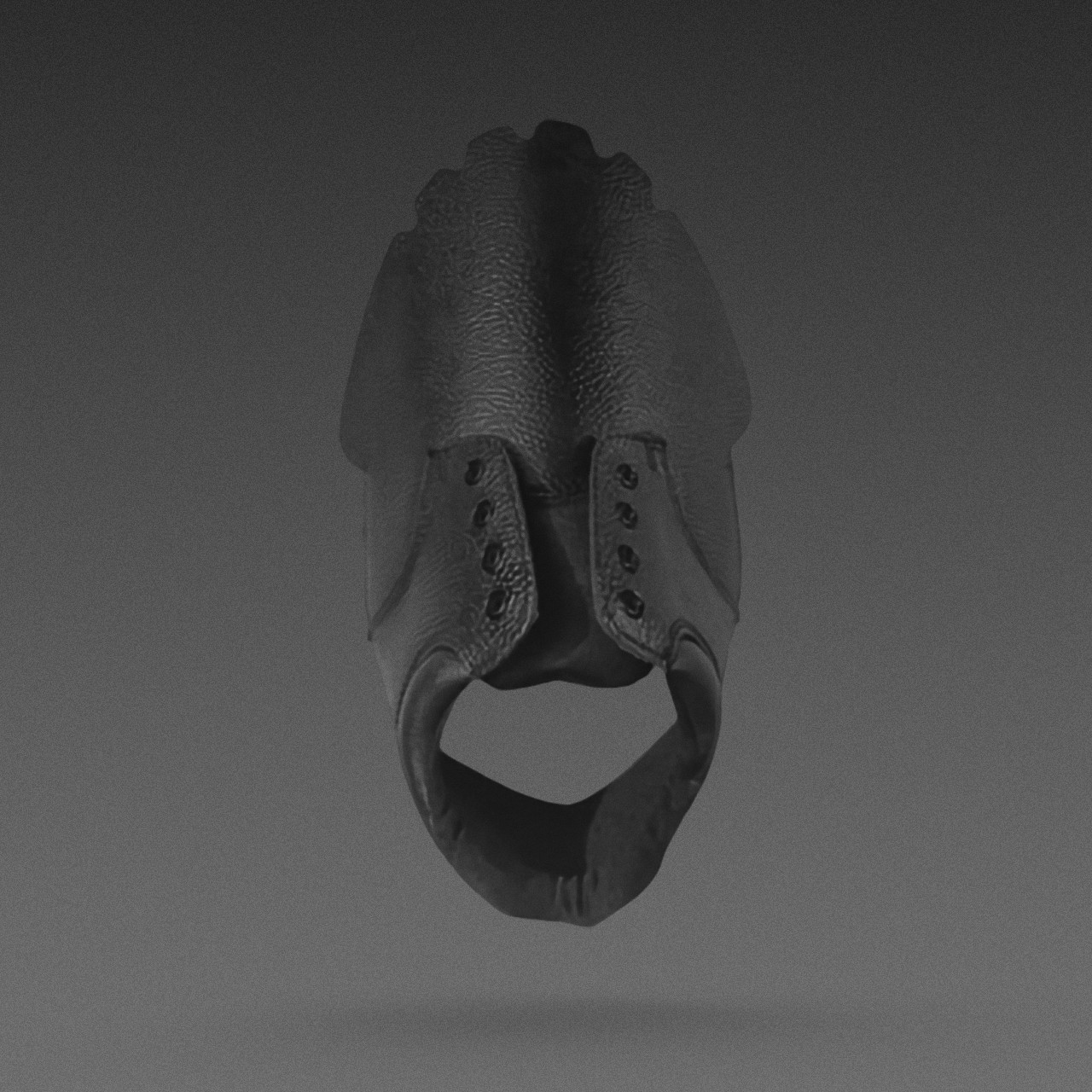

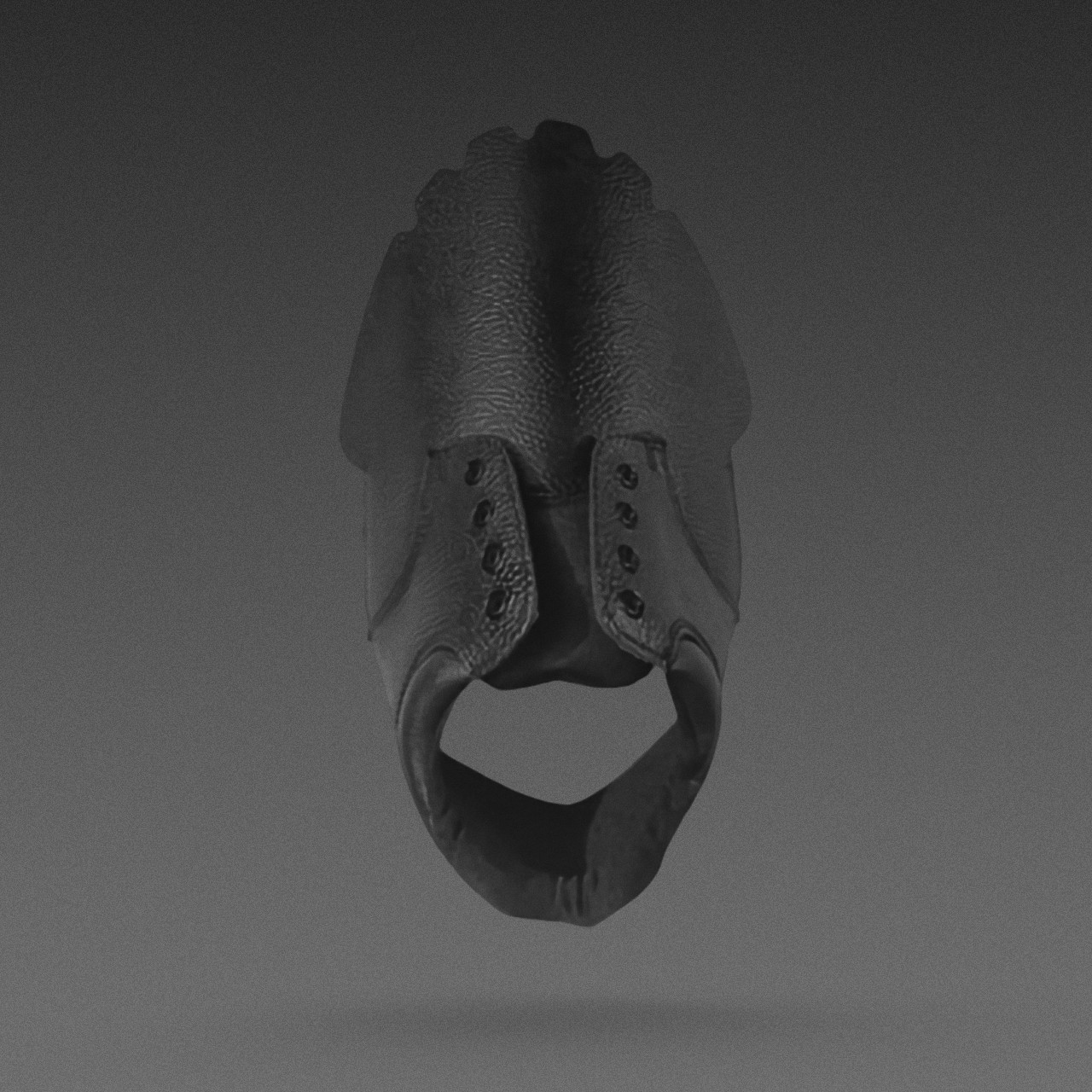

Uppers

Toe Cap

PU

Single Density

Features

Anti-static

Heat Resistant (upto 120° C)

Anti-skid properties

PU/PU

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(PU)

Excellent abrasion resistant

Anti-static properties

Heat resistant (upto 120° C)

Anti-skid properties

PU/Rubber

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(Rubber)

Heat resistant (upto 300° C)

EVA

Moulded Cushion

Features

Thin insock

Precision moulded

Comfortable cushion

PU

Insock

Features

Excellent comfort

Extremely light-weight

Keeps knees & feet fit

Leather

Uppers

Features

Stylish & sturdy looks

Long lasting material

Breathable leather

Keeps feet fresh

Microfiber

Uppers

Features

Animal free

Breathable material

Stylish & sturdy looks

Long lasting material

Steel

Toecap

Features

200J steel

Protective steel toe

Safe guards feet

Composite

Toecap

Features

Light-weight composite

Composite toe

For electircal applications

Soles

Insock

Uppers

Toe Cap

PU

Single Density

Features

Anti-static

Heat Resistant (upto 120° C)

Anti-skid properties

PU/PU

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(PU)

Excellent abrasion resistant

Anti-static properties

Heat resistant (upto 120° C)

Anti-skid properties

PU/Rubber

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(Rubber)

Heat resistant (upto 300° C)

EVA

Moulded Cushion

Features

Thin insock

Precision moulded

Comfortable cushion

PU

Insock

Features

Excellent comfort

Extremely light-weight

Keeps knees & feet fit

Leather

Uppers

Features

Stylish & sturdy looks

Long lasting material

Breathable leather

Keeps feet fresh

Microfiber

Uppers

Features

Animal free

Breathable material

Stylish & sturdy looks

Long lasting material

Steel

Toecap

Features

200J steel

Protective steel toe

Safe guards feet

Composite

Toecap

Features

Light-weight composite

Composite toe

For electircal applications

Soles

Insock

Uppers

Toe Cap

PU

Single Density

Features

Anti-static

Heat Resistant (upto 120° C)

Anti-skid properties

PU/PU

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(PU)

Excellent abrasion resistant

Anti-static properties

Heat resistant (upto 120° C)

Anti-skid properties

PU/Rubber

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(Rubber)

Heat resistant (upto 300° C)

EVA

Moulded Cushion

Features

Thin insock

Precision moulded

Comfortable cushion

PU

Insock

Features

Excellent comfort

Extremely light-weight

Keeps knees & feet fit

Leather

Uppers

Features

Stylish & sturdy looks

Long lasting material

Breathable leather

Keeps feet fresh

Microfiber

Uppers

Features

Animal free

Breathable material

Stylish & sturdy looks

Long lasting material

Steel

Toecap

Features

200J steel

Protective steel toe

Safe guards feet

Composite

Toecap

Features

Light-weight composite

Composite toe

For electircal applications

Soles

Insock

Uppers

Toe Cap

PU

Single Density

Features

Anti-static

Heat Resistant (upto 120° C)

Anti-skid properties

PU/PU

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(PU)

Excellent abrasion resistant

Anti-static properties

Heat resistant (upto 120° C)

Anti-skid properties

PU/Rubber

Double Density

Midsole

(PU)

Serving as a cushion

Comfortable cushion

Outersole

(Rubber)

Heat resistant (upto 300° C)

EVA

Moulded Cushion

Features

Thin insock

Precision moulded

Comfortable cushion

PU

Insock

Features

Excellent comfort

Extremely light-weight

Keeps knees & feet fit

Leather

Uppers

Features

Stylish & sturdy looks

Long lasting material

Breathable leather

Keeps feet fresh

Microfiber

Uppers

Features

Animal free

Breathable material

Stylish & sturdy looks

Long lasting material

Steel

Toecap

Features

200J steel

Protective steel toe

Safe guards feet

Composite

Toecap

Features

Light-weight composite

Composite toe

For electircal applications

Manufacturing

Manufacturing

Manufacturing

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

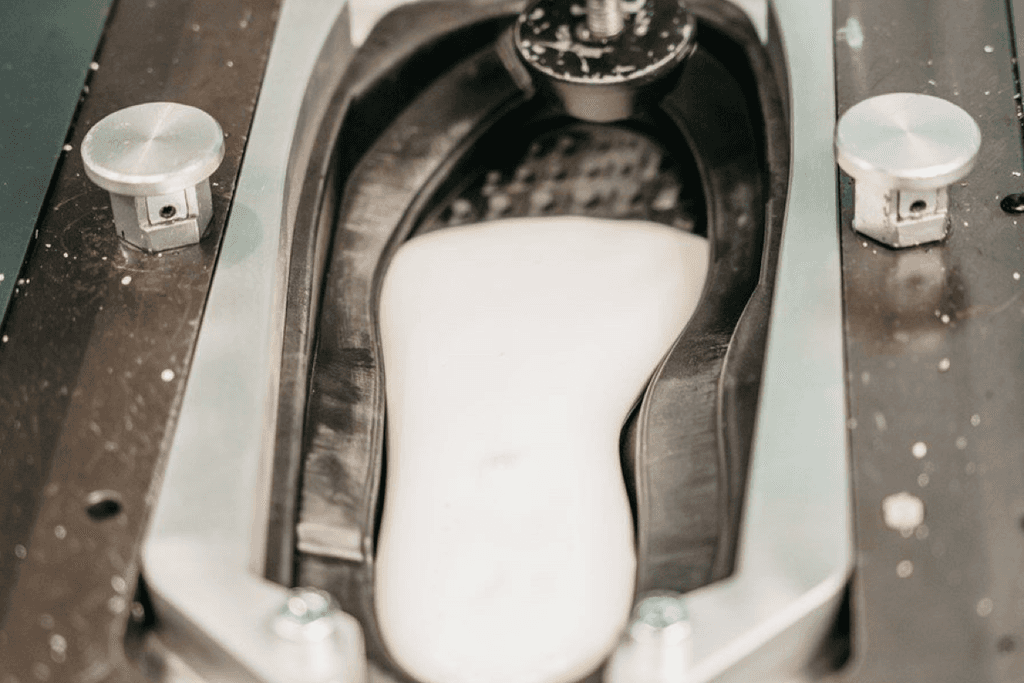

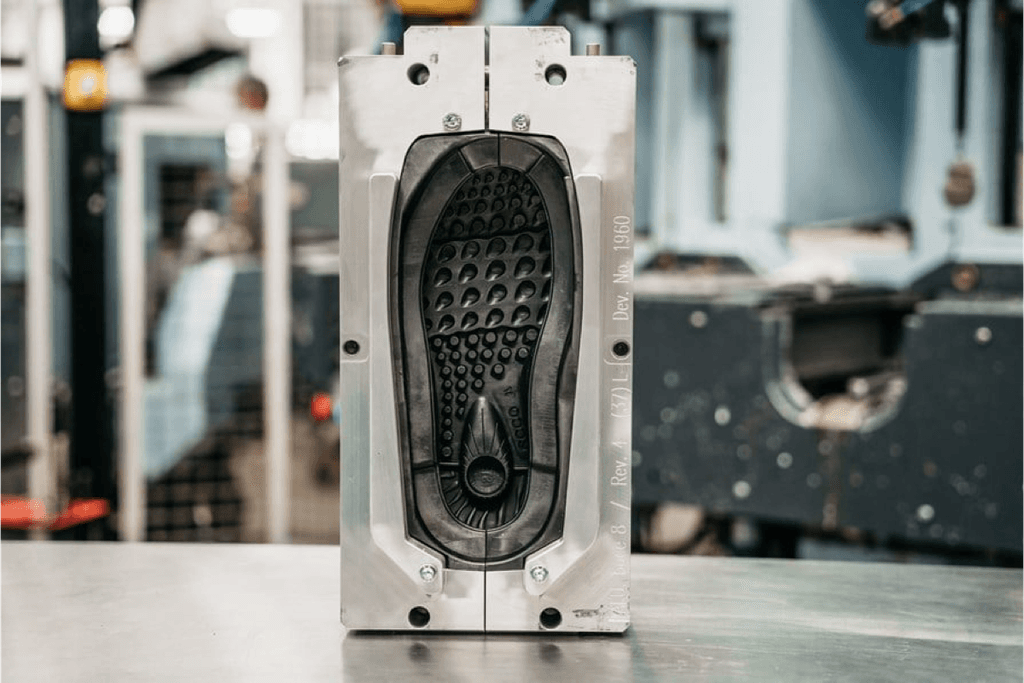

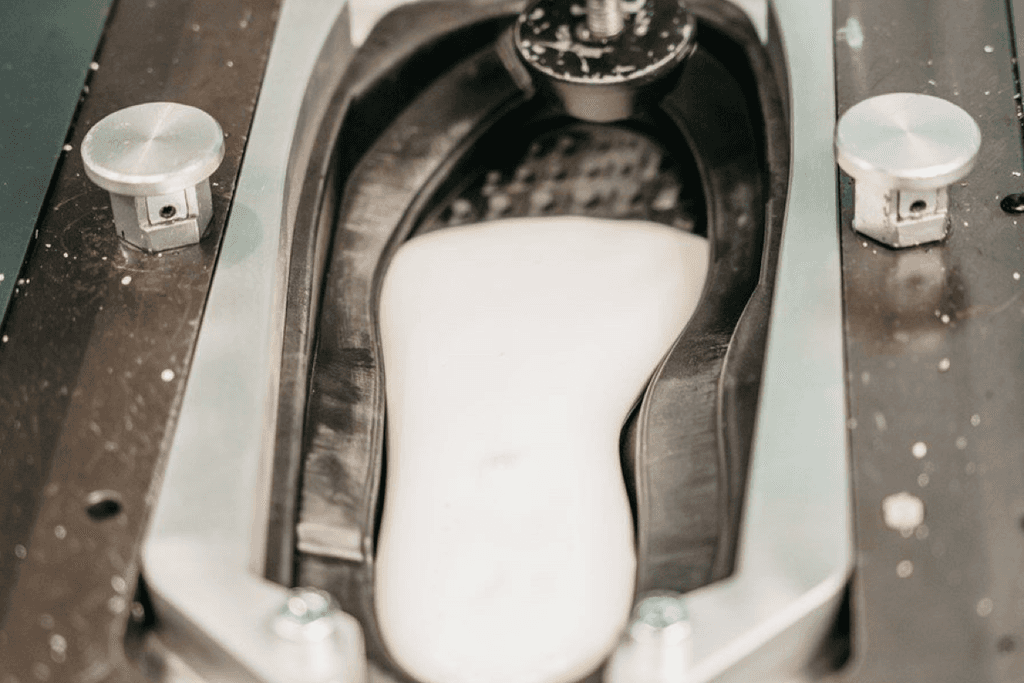

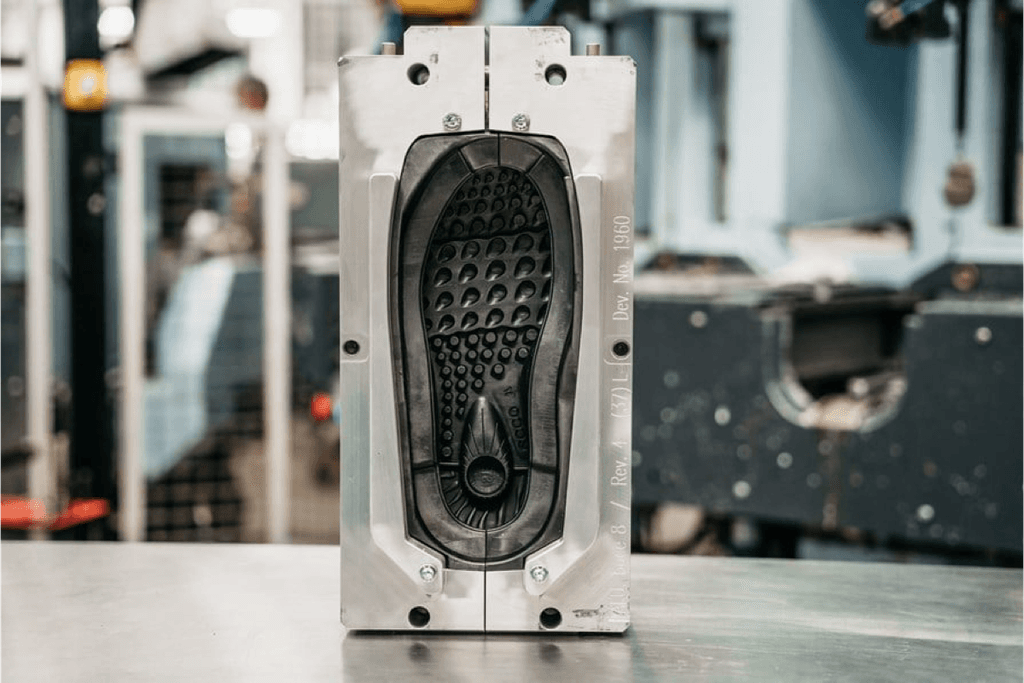

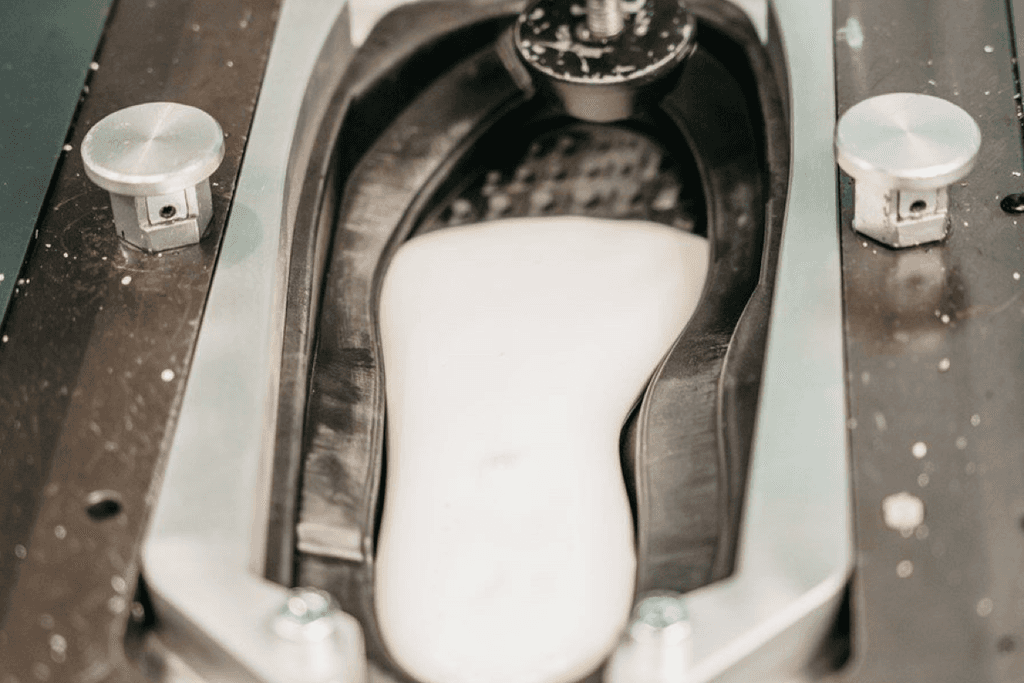

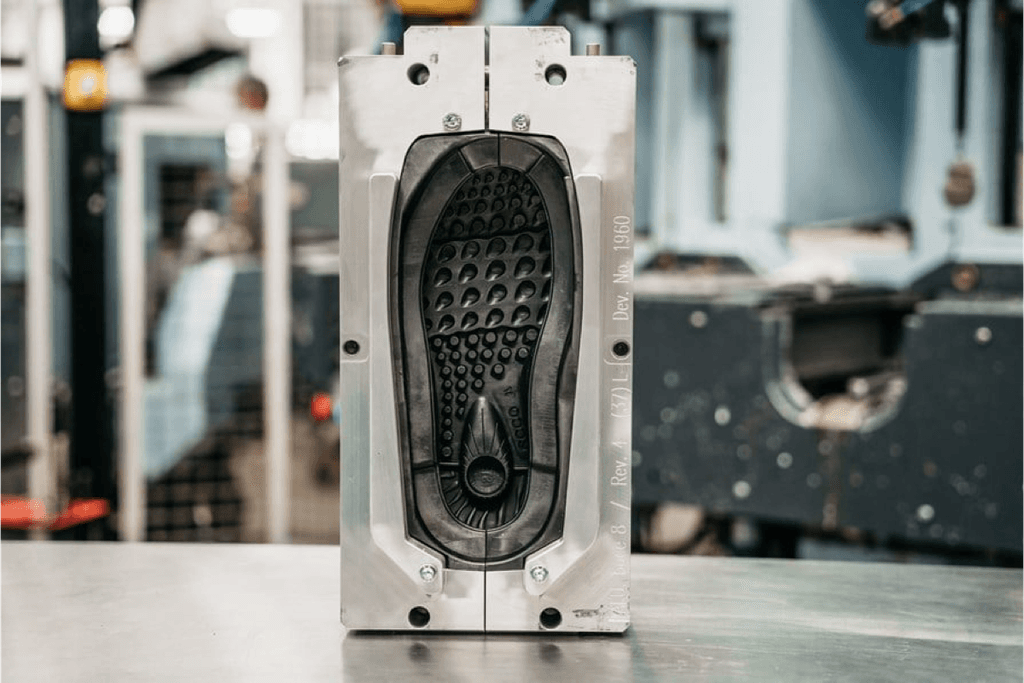

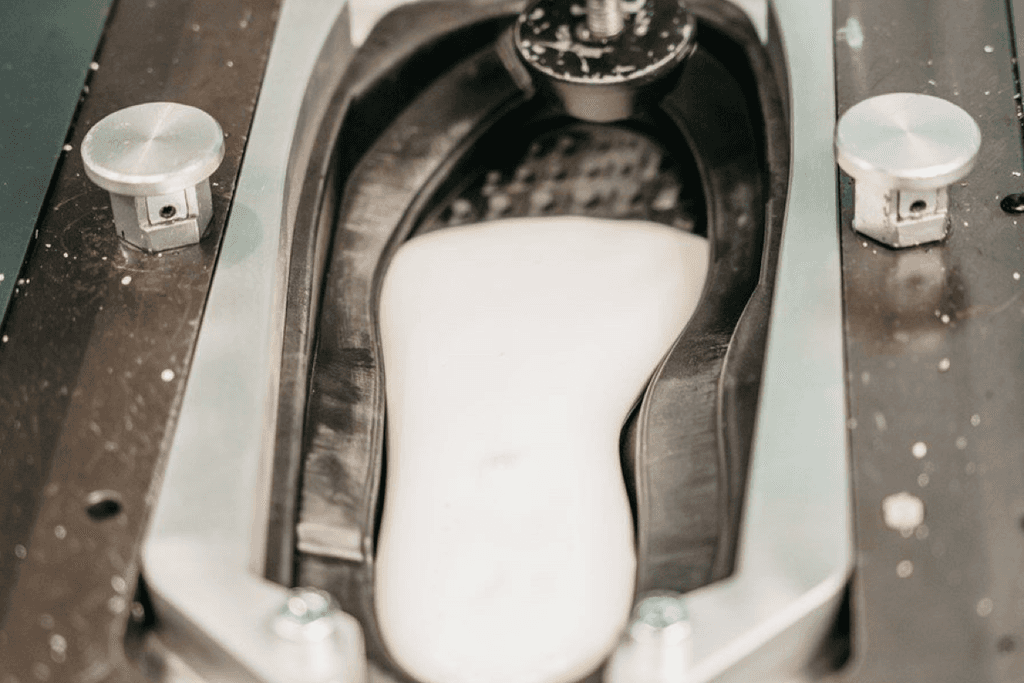

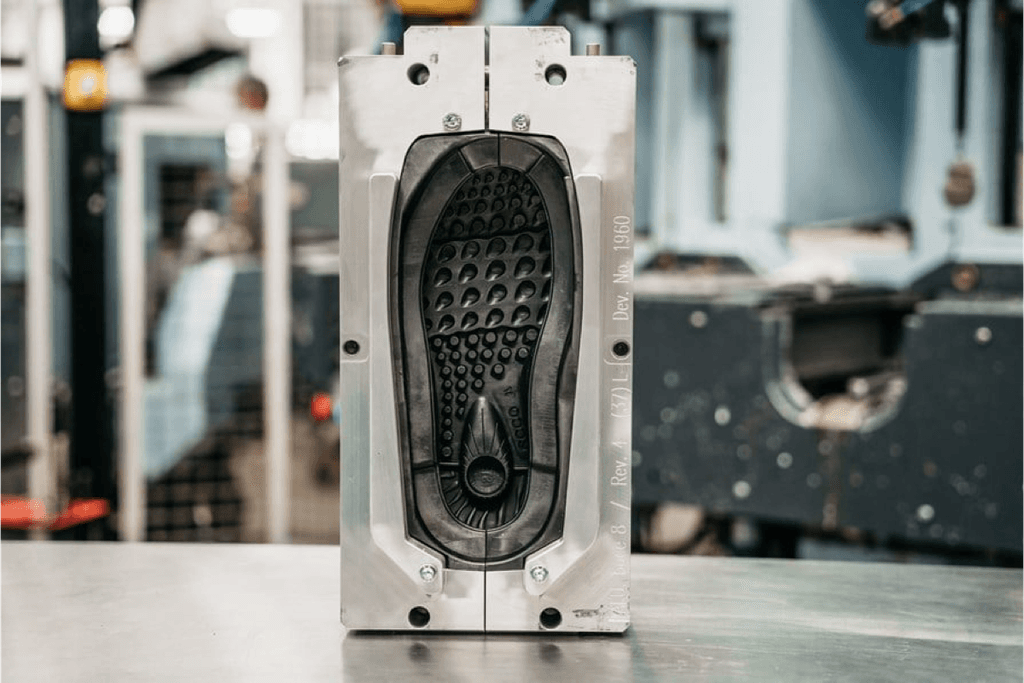

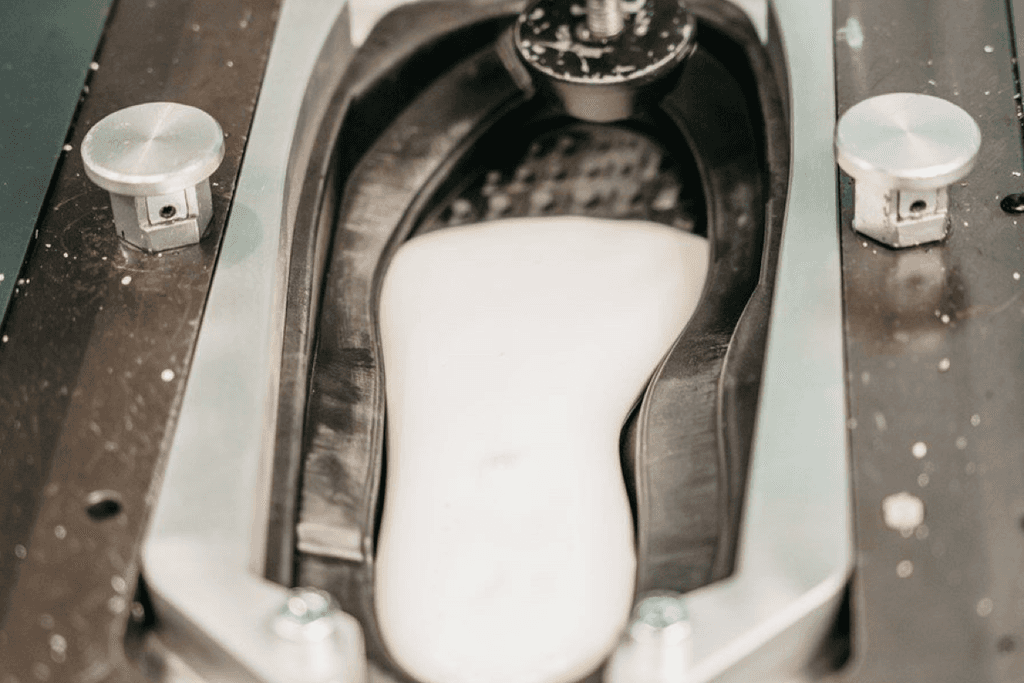

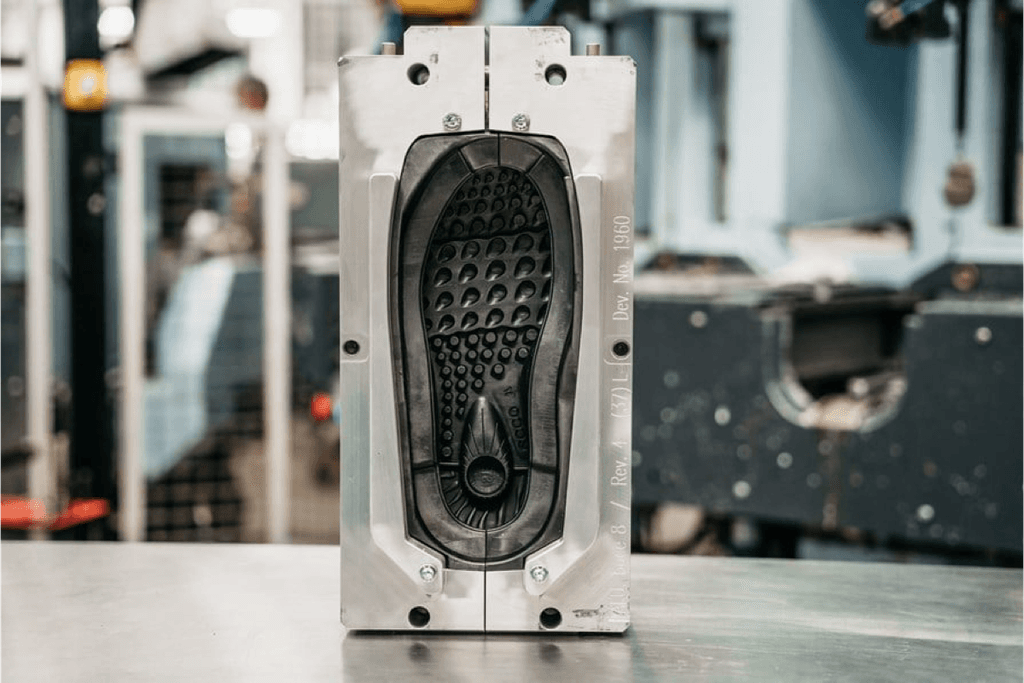

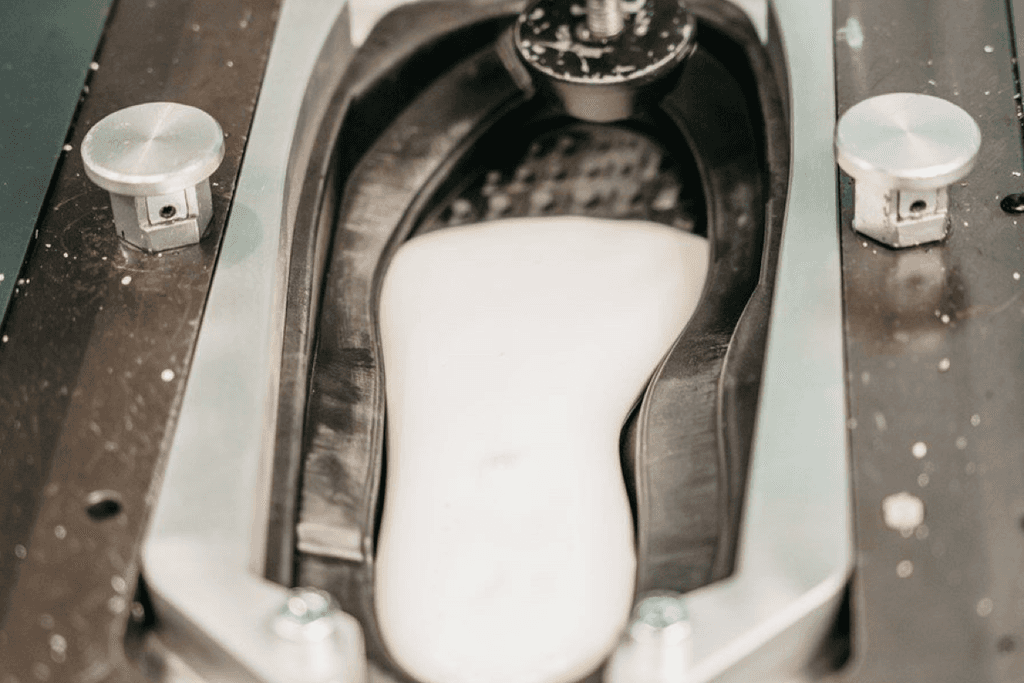

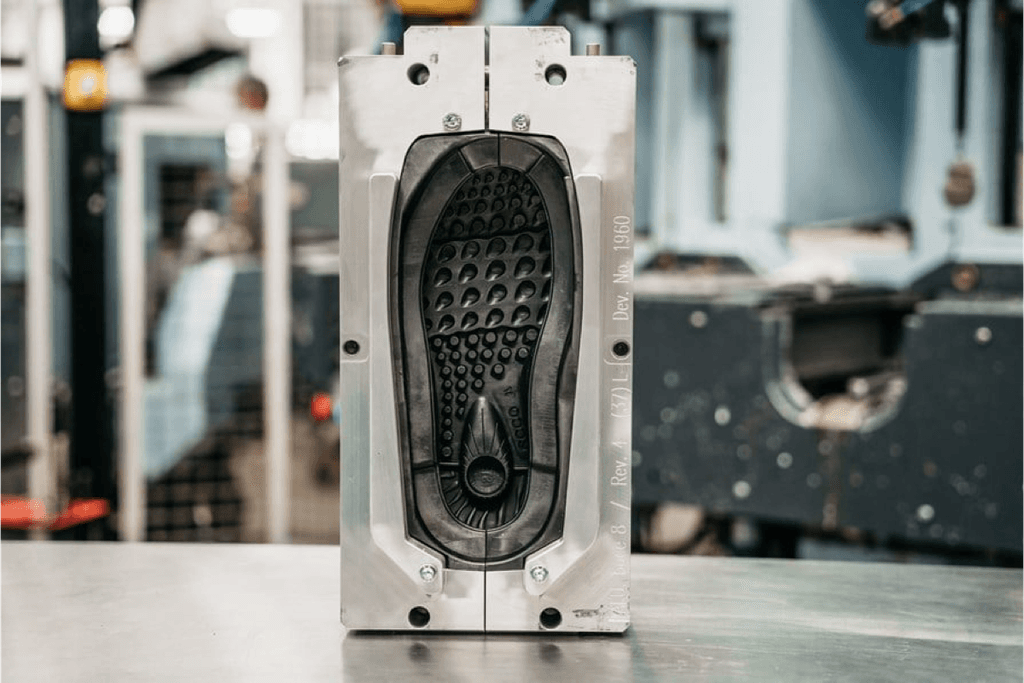

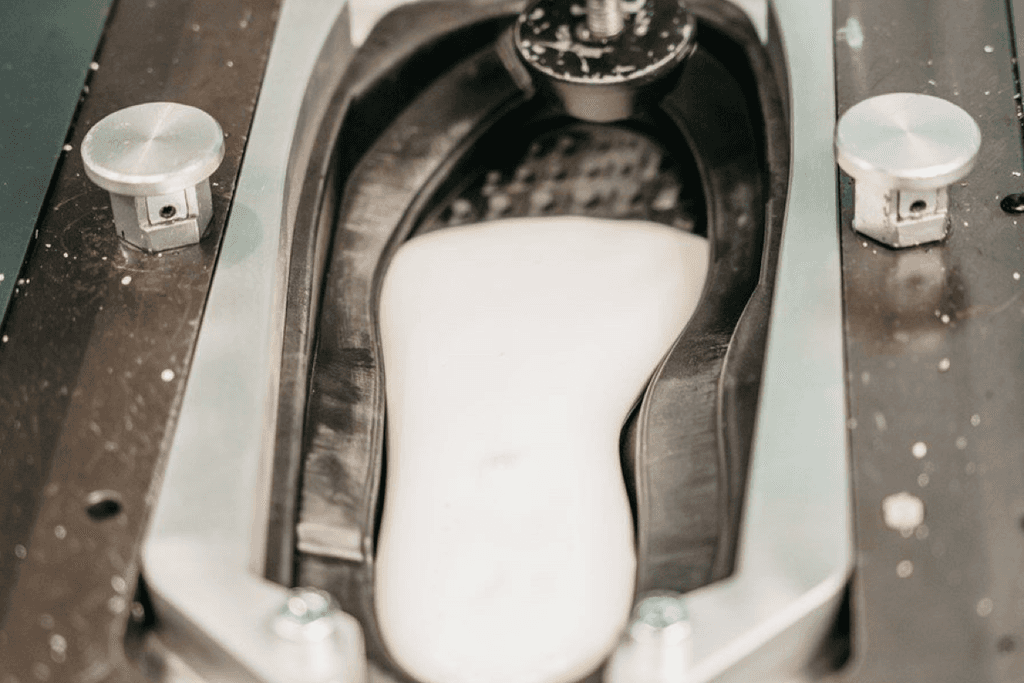

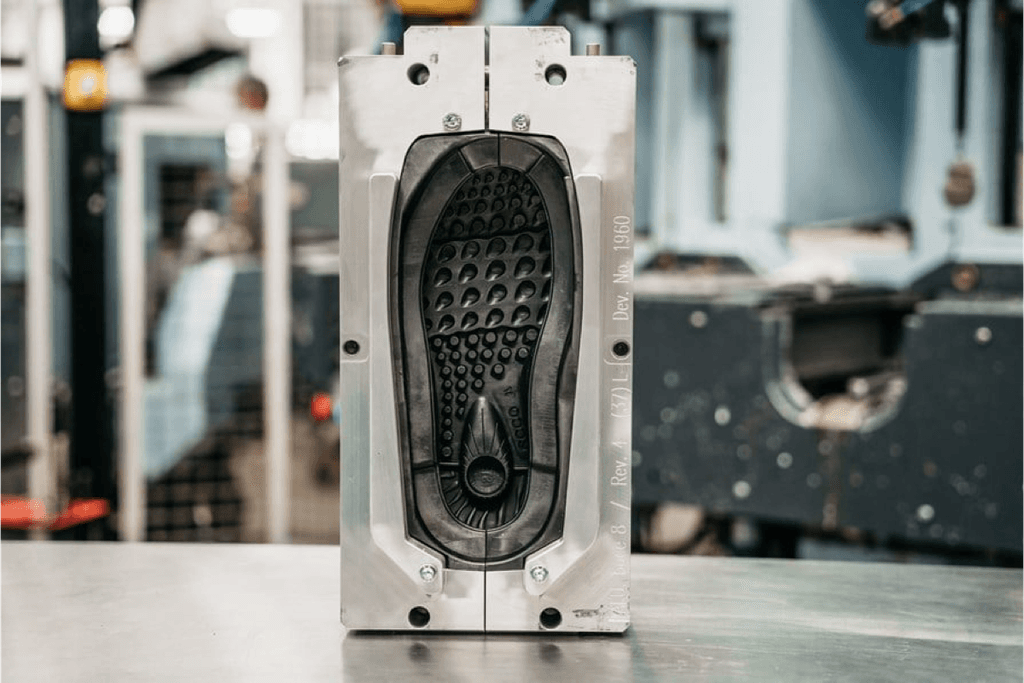

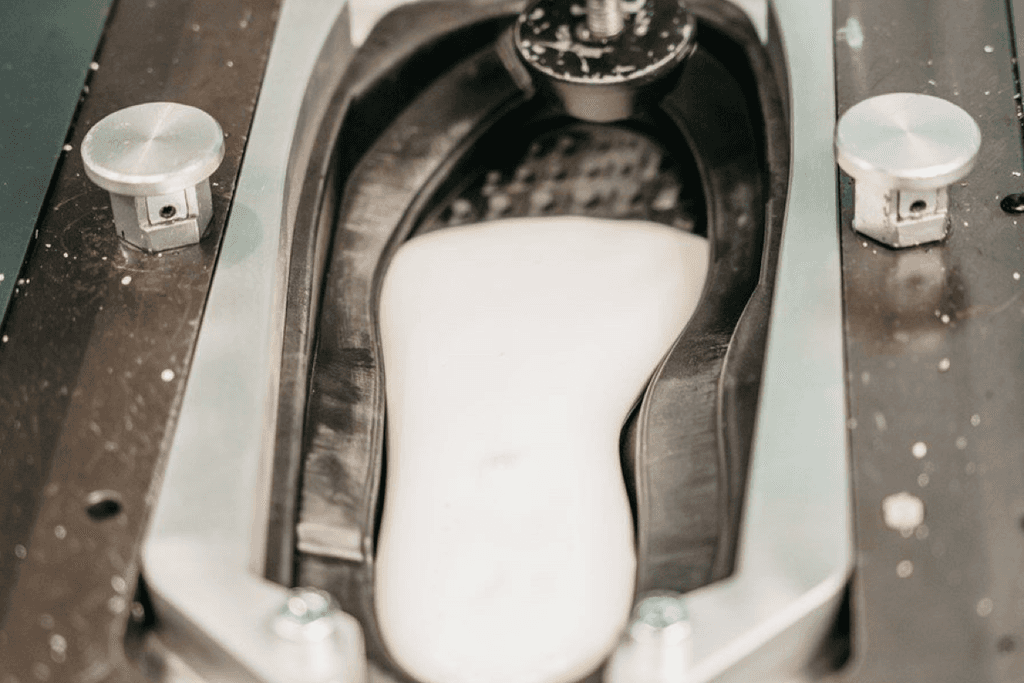

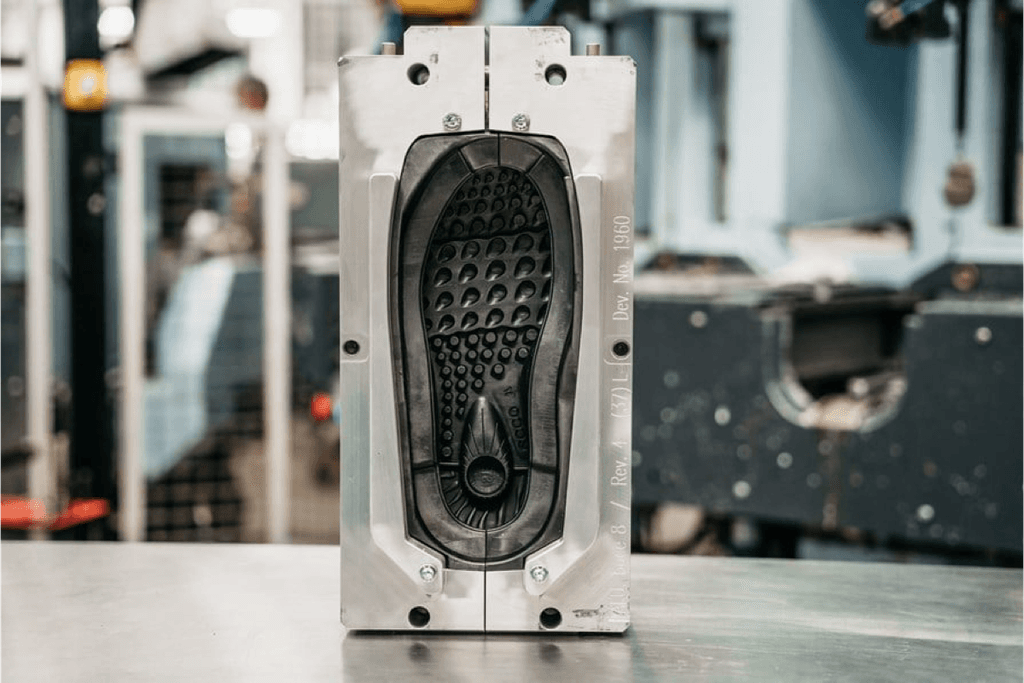

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Design & Development

The designing and development department is equipped with the latest software, featuring 2 dedicated designers and a prototype sample-making team. It also includes technical personnel responsible for creating product specification sheets

Injection moulding

Our production capacity with 2 direct injection machines is 25,000 pairs of shoes per month. Each PU cup sample and tested sole is kept for traceability for over 6 months

Quality control

We monitor each stage—from raw materials to final assembly—recording inspections and reporting deviations for correction. Each shoe pair has a unique code for tracking production and quality control

Packaging

Our plant has 5 conveyor lines for the complete finishing and packaging of shoes according to customer requirements

Safety Standards

Safety Standards

Safety Standards

Safety Category

(S1)

Safety Category

(S1)

Safety Category

(S1)

Safety Category

(S2)

Safety Category

(S2)

Safety Category

(S2)

Safety Category

(S3)

Safety Category

(S3)

Safety Category

(S3)

Safety Category

(S4)

Safety Category

(S4)

Safety Category

(S4)

Contact Sales

Contact Sales

Contact us about anything related to our company or services.

We will do our best to get back to you as soon as possible.

Contact us about anything related to our company or services.

We will do our best to get back to you as soon as possible.

Contact Sales

Contact us about anything related to our company or services.

We will do our best to get back to you as soon as possible.

Reach us at

Reach us at

Reach us at

Vadodara Office

Vadodara Office

Vadodara Office

502, 5th Floor, Krishna Platina,

Opp Earth Icon,Nr Khodiyar

Cross Roads, New VIP Road,

Vadodara 390019

502, 5th Floor, Krishna Platina,

Opp Earth Icon,Nr Khodiyar

Cross Roads, New VIP Road,

Vadodara 390019

502, 5th Floor, Krishna Platina,

Opp Earth Icon,Nr Khodiyar

Cross Roads, New VIP Road,

Vadodara 390019

Ahmedabad office

Ahmedabad office

Ahmedabad office

C-721, Siddhi Vinayak Tower,

Besides Kataria House,

Makarba, Ahmedabad,

Gujarat 380051

C-721, Siddhi Vinayak Tower,

Besides Kataria House,

Makarba, Ahmedabad,

Gujarat 380051

C-721, Siddhi Vinayak Tower,

Besides Kataria House,

Makarba, Ahmedabad,

Gujarat 380051

For More Information

For More Information

For More Information

safety@contablue.com

+91 98981 61998

+91-73599 52952

safety@contablue.com

+91 98981 61998

+91-73599 52952

safety@contablue.com

+91 98981 61998

+91-73599 52952